What Is Lean Manufacturing Principles Advantages Examples

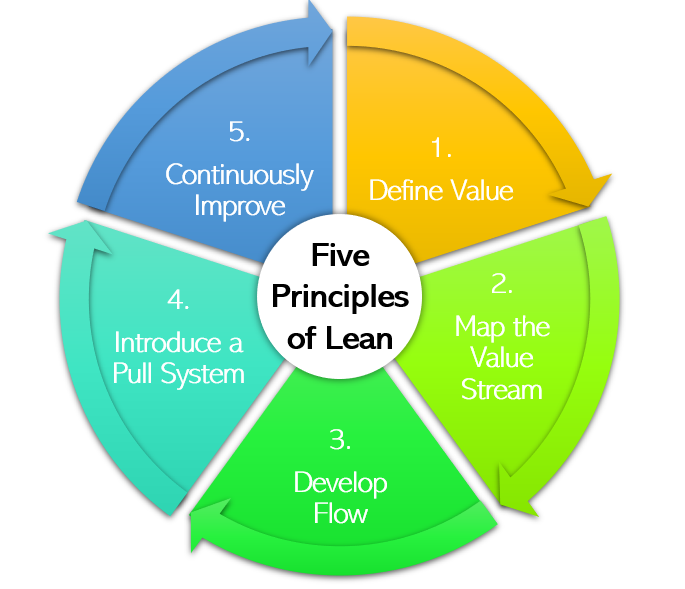

The 5 Principles Of Lean And How To Apply Them Lean Outside The Box The five core principles of lean manufacturing are defined as value, the value stream, flow, pull and perfection. these are now used as the basis to implement lean. 1. value: value is determined from the perspective of the customer and relates to how much they are willing to pay for products or services. The five principles of lean manufacturing – value, value stream, flow, pull, and perfection – provide a powerful framework for improving efficiency, reducing waste, and delivering superior value to customers. while each principle is important in its own right, they are most effective when implemented together as an integrated system.

Why Implement Lean Manufacturing In Manufacturing Project Management 5) perfection. another essential lean manufacturing principle to consider is perfection. just like in any other aspect of business, achieving perfection starts with a conscious decision to strive for excellence. while it may sound simple, adopting a culture of perfection takes time and effort. Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Benefits of lean manufacturing. lean manufacturing has gained such popularity for a reason—it works. more specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. lean manufacturing also results in improved customer service, higher quality. Often, people use the terms “lean manufacturing” and “agile manufacturing” interchangeably. despite their similar sounding names, lean manufacturing and agile manufacturing are two different methods with their own principles, goals, and techniques. check out the agile manufacturing vs lean manufacturing differences.

Benefits And Advantages Of Lean Manufacturing Toughnickel Benefits of lean manufacturing. lean manufacturing has gained such popularity for a reason—it works. more specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. lean manufacturing also results in improved customer service, higher quality. Often, people use the terms “lean manufacturing” and “agile manufacturing” interchangeably. despite their similar sounding names, lean manufacturing and agile manufacturing are two different methods with their own principles, goals, and techniques. check out the agile manufacturing vs lean manufacturing differences. The core principles of lean manufacturing are: value: the first principle of lean manufacturing is to identify and focus on the value that a product or service provides to the customer. all activities in the manufacturing process should be aimed at delivering this value to the customer, while minimizing waste. flow: the second principle of lean. Wip is a sign that a process needs improving and is a type of waste to eliminate. improve system by eliminating waste and improving current processes. everyone is empowered, trained in the key principles of lean and encouraged to look for ways to improve processes. always looking for ways to improve processes and people.

Lean Manufacturing Principles The core principles of lean manufacturing are: value: the first principle of lean manufacturing is to identify and focus on the value that a product or service provides to the customer. all activities in the manufacturing process should be aimed at delivering this value to the customer, while minimizing waste. flow: the second principle of lean. Wip is a sign that a process needs improving and is a type of waste to eliminate. improve system by eliminating waste and improving current processes. everyone is empowered, trained in the key principles of lean and encouraged to look for ways to improve processes. always looking for ways to improve processes and people.

The Five Principles Of Lean

Comments are closed.