What Are The Benefits Of Closed Circuit Cooling Towers

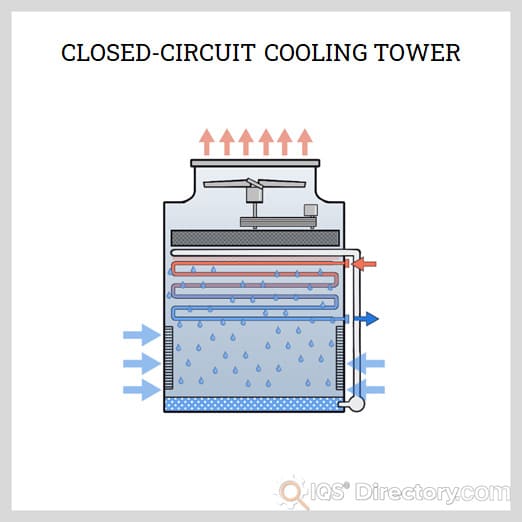

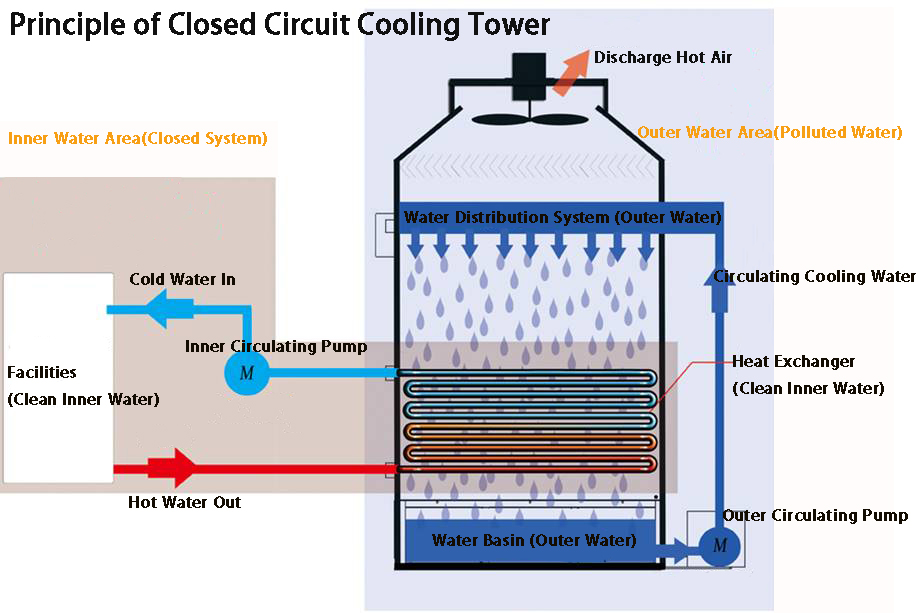

Open Loop Closed Loop Cooling Towers Uses Benefits Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil. Sometimes, an open cooling tower is paired with a heat exchanger (see figure 3) to capture some of the benefits of closed loop cooling. choosing closed circuit cooling towers over this open tower heat exchanger combination may still be a better choice for the following reasons: total cost: addition of a heat exchanger (pump, piping, etc.) to.

Principle Of Closed Circuit Cooling Tower Closed Circuit Cool More about closed circuit cooling towers. a closed circuit cooling tower, or dry cooling tower, involves no contact between the air and the fluid being cooled. this tower has two separate fluid circuits, one in which the fluid is recirculated on the outside of the second circuit, which is a bundle of tubes through which the hot water is flowing. A closed circuit cooling tower can be an alternative to a system composed by an open circuit cooling tower and a heat exchanger. this leads to some advantage: easier plant layout. reduced footprint. higher thermal efficiency. cooling tower: operation and use. Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger. Different types of closed circuit cooling towers. there are four primary types of closed loop cooling towers. evaporative closed circuit coolers: this type of closed circuit coolers eliminates the need for a heat exchanger between the process loop and the heat rejection equipment. unlike a cooling tower, where process water is used as the.

Closed Circuit Cooling Tower Advantages Vs Open Loop Towers Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger. Different types of closed circuit cooling towers. there are four primary types of closed loop cooling towers. evaporative closed circuit coolers: this type of closed circuit coolers eliminates the need for a heat exchanger between the process loop and the heat rejection equipment. unlike a cooling tower, where process water is used as the. Evaporative closed circuit coolers eliminate the need for a heat exchanger between the process loop and the heat rejection equipment. unlike a cooling tower, where process water is used as the energy transfer medium and is open to the atmosphere, the coil inside a closed circuit cooler isolates the process fluid. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil.

Contamination Free Cooling The Advantages Of Closed Circuit Cooling Evaporative closed circuit coolers eliminate the need for a heat exchanger between the process loop and the heat rejection equipment. unlike a cooling tower, where process water is used as the energy transfer medium and is open to the atmosphere, the coil inside a closed circuit cooler isolates the process fluid. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil.

Comments are closed.