Types Of Machine Maintenance To Perform Regularly

Types Of Machine Maintenance To Perform Regularly 1. preventive maintenance. preventive maintenance is one of the most common types of maintenance that is used in the field service, commercial and construction industry. this type of maintenance helps to maintain performance on a set schedule. preventive maintenance will either be set on a usage or time based schedule. Preventive maintenance (pm) is a proactive maintenance strategy aimed at reducing the likelihood of machine failure by performing regular maintenance tasks. pm tasks are scheduled based on time or usage cycles, ensuring that machinery and equipment are regularly maintained. types of assets it is best used for.

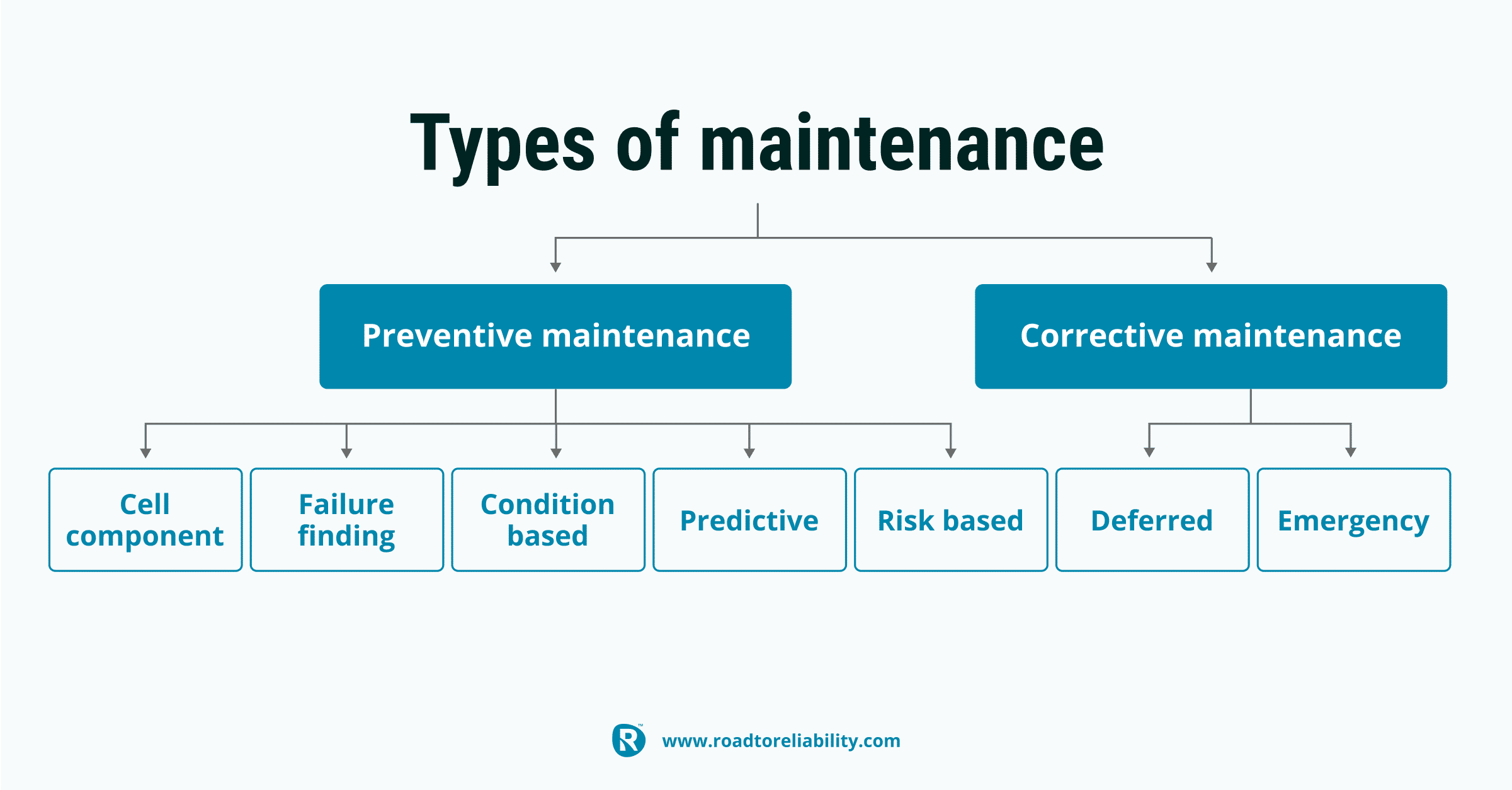

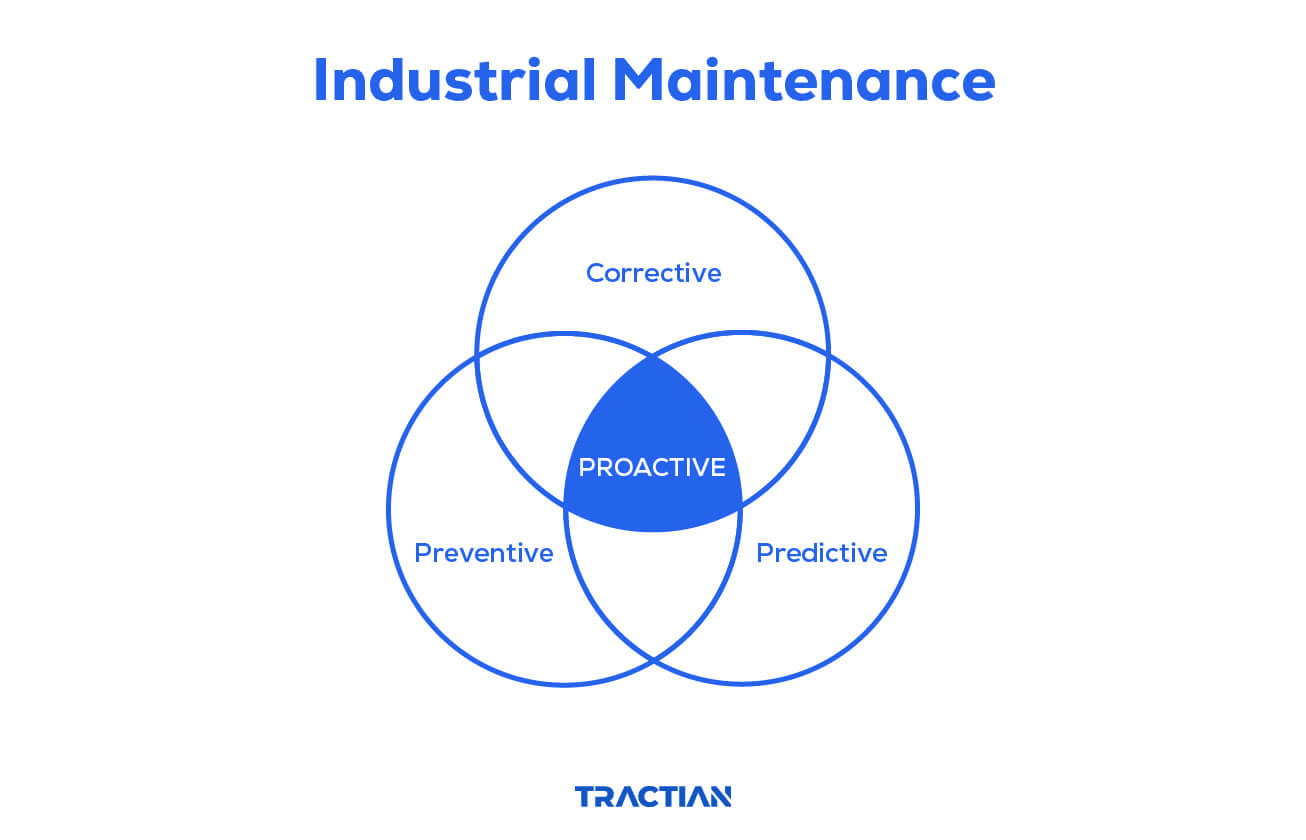

6 Types Of Maintenance Explained вђ Best Maintenance Toolsense Preventive maintenance is commonly used to maintain a facility’s assets such as hvac machines, and reactive maintenance is mainly used to keep the areas of a facility in good operating conditions such as painting of the walls. property maintenance. Predictive maintenance is the most advanced type of maintenance, but it also requires the most sophisticated data analysis tools. in addition to the four main types of maintenance, there are a number of other factors that large enterprises should consider when developing a machine maintenance plan. these factors include:. The 5 types of machine maintenance. there are five machine maintenance types: preventative maintenance, predictive maintenance, corrective maintenance, routine maintenance, and emergency maintenance. each of these types is essential—but ideally, you’ll be able to avoid corrective and emergency maintenance by scheduling predictive. There are eight key types of maintenance strategies that organizations use to ensure that their equipment is running efficiently and effectively. these include: preventive maintenance: regularly scheduled maintenance to prevent equipment failures; corrective maintenance: repairing equipment after a failure has occurred.

9 Types Of Maintenance Choosing The Right Maintenance Types The 5 types of machine maintenance. there are five machine maintenance types: preventative maintenance, predictive maintenance, corrective maintenance, routine maintenance, and emergency maintenance. each of these types is essential—but ideally, you’ll be able to avoid corrective and emergency maintenance by scheduling predictive. There are eight key types of maintenance strategies that organizations use to ensure that their equipment is running efficiently and effectively. these include: preventive maintenance: regularly scheduled maintenance to prevent equipment failures; corrective maintenance: repairing equipment after a failure has occurred. Machine maintenance is the work that keeps mechanical assets running with minimal downtime. machine maintenance can include regularly scheduled service, routine checks, and both scheduled and emergency repairs. it also includes replacement or realignment of parts that are worn, damaged, or misaligned. machine maintenance can be done either in. Machine maintenance is all about making sure that machines work well and don’t experience too much unexpected downtime. this means a combination of regular checkups, planned maintenance, and on the spot repairs in addition to the replacement of worn out parts. every industry that uses machines, such as manufacturing and utilities, needs good.

Types Of Maintenance The Complete Guide Machine maintenance is the work that keeps mechanical assets running with minimal downtime. machine maintenance can include regularly scheduled service, routine checks, and both scheduled and emergency repairs. it also includes replacement or realignment of parts that are worn, damaged, or misaligned. machine maintenance can be done either in. Machine maintenance is all about making sure that machines work well and don’t experience too much unexpected downtime. this means a combination of regular checkups, planned maintenance, and on the spot repairs in addition to the replacement of worn out parts. every industry that uses machines, such as manufacturing and utilities, needs good.

Comments are closed.