Ttt Diagrams Ttt Diagram For Heat Treatment Of Steel Tt

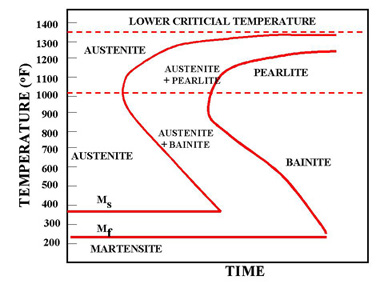

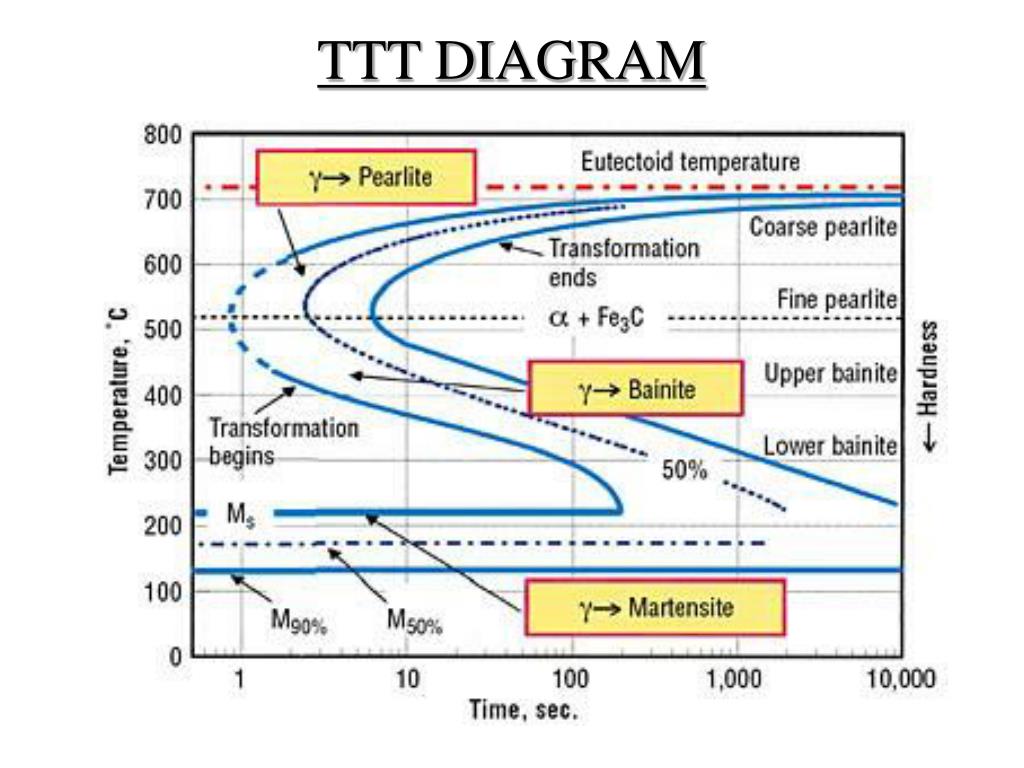

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Introduction. both temperature & time i.e. rate of cooling is taken in consideration. ttt – time temperature transformation. a plot of temperature versus log of time. steel alloy of definite composition. determines when transformations begin and end for an isothermal (constant temp.) phase transformation of a previously austenitized alloy. Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy.

Ttt Diagrams Ttt Diagram For Heat Treatment Of Steel Tt Ttt diagrams, or time temperature transformation diagrams, are graphical representations that illustrate the transformation behavior of materials as a function of time and temperature. these diagrams are commonly used in the field of metallurgy to predict the formation of different microstructures in various alloys and steels. the ttt diagram. Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1. Ttt diagram gives. ttt diagram is used to find out the following parameters, 1 nature and type of transformation. 2 rate of transformation. 3 stability of phases under isothermal transformation conditions. 4 temperature or time required to start or finish the transformation. 5 qualitative information about the size scale of the product. In large number of commercial heat treatment, the transformations occur during continuous cooling of the steel, and the information from ttt diagrams is not directly useful to these heat treatments. however, ttt diagrams are the basis of certain heat treatments in which transformations occur isothermally, such as: 1. martempering: it is a hardening process with an objective to minimise.

2 Typical Ttt Diagram For Steel Hoe96 Download Scientific Diagram Ttt diagram gives. ttt diagram is used to find out the following parameters, 1 nature and type of transformation. 2 rate of transformation. 3 stability of phases under isothermal transformation conditions. 4 temperature or time required to start or finish the transformation. 5 qualitative information about the size scale of the product. In large number of commercial heat treatment, the transformations occur during continuous cooling of the steel, and the information from ttt diagrams is not directly useful to these heat treatments. however, ttt diagrams are the basis of certain heat treatments in which transformations occur isothermally, such as: 1. martempering: it is a hardening process with an objective to minimise. Isothermal transformation diagrams (also known as time temperature transformation (ttt) diagrams) are plots of temperature versus time (usually on a logarithmic scale). they are generated from percentage transformation vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures. Here we show a variety of different steel microstructure outcomes depending on different ttt diagram heat treatments.

Diagram Welding Ttt Diagram Wiringschema Com Isothermal transformation diagrams (also known as time temperature transformation (ttt) diagrams) are plots of temperature versus time (usually on a logarithmic scale). they are generated from percentage transformation vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures. Here we show a variety of different steel microstructure outcomes depending on different ttt diagram heat treatments.

Comments are closed.