Ttt Diagram Metallurgy For Dummies

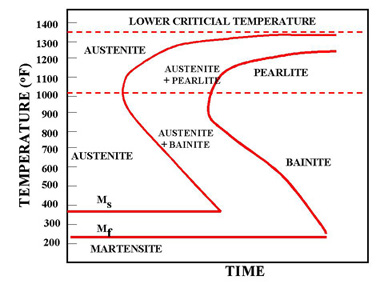

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy.

Fe Fe3c T T T Diagram Metallurgy For Dummies Fe fe 3 c t t t diagram, adapted from callister pg. 295, fig. 10.6. the time temperature transformation curves correspond to the start and finish of transformations which extend into the range of temperatures where austenite transforms to pearlite. above 550 c, austenite transforms completely to pearlite. below 550 c, both pearlite and bainite. A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. There are two main types of transformation diagram that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. these are time temperature transformation (ttt) and continuous cooling transformation (cct) diagrams. cct diagrams are generally more appropriate for engineering applications as components. In this video, you will learn about the ttt plots and how they are formed.📺 subscribe to my channel here: c profdrvasimashaikh?sub c.

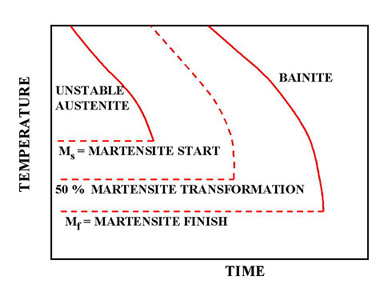

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies There are two main types of transformation diagram that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. these are time temperature transformation (ttt) and continuous cooling transformation (cct) diagrams. cct diagrams are generally more appropriate for engineering applications as components. In this video, you will learn about the ttt plots and how they are formed.📺 subscribe to my channel here: c profdrvasimashaikh?sub c. Institute of technology, banaras hindu university. varanasi 221 005, india. [email protected]. tata steel traerf faculty fellowship visiting scholar department of materials science and metallurgy university of cambridge, pembroke street, cambridge, cb2 3qz [email protected]. Time temperature transformation diagram for two steels: one with 0.4% wt. c (red line) and one with 0.4% wt. c and 2% weight mn (green line). p = pearlite, b = bainite and m = martensite. isothermal transformation diagrams (also known as time temperature transformation ( ttt ) diagrams ) are plots of temperature versus time (usually on a.

Comments are closed.