Time Temperature Transformation Ttt Diagram

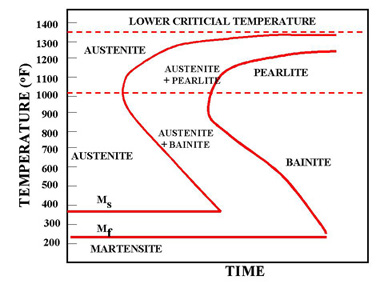

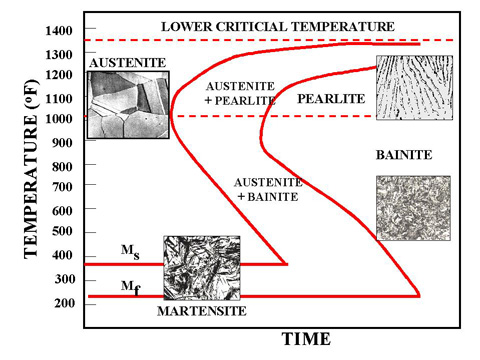

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Salt bath i (fig. 1) is maintained at austenetising temperature (780 ̊c for eutectoid steel). salt bath ii (fig. 2) is maintained at specified temperature at which transformation is to be determined (below ae1), typically 700 250°c for eutectoid steel. bath iii which is a cold water bath is maintained at room temperature. Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy.

Time Temperature Transformation Ttt Diagram Mechanicstips Time temperature transformation diagram for two steels: one with 0.4% wt. c (red line) and one with 0.4% wt. c and 2% weight mn (green line). p = pearlite, b = bainite and m = martensite. isothermal transformation diagrams (also known as time temperature transformation ( ttt ) diagrams ) are plots of temperature versus time (usually on a. A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. Time temperature precipitation diagrams and time temperature embrittlement diagrams have also been used to represent kinetic changes in steels. the ttt diagram for aisi 1080 steel (0.79%c, 0.76%mn) austenitized at 900°c . time temperature transformation for steel. isothermal transformation (it). The kinetics of such complexion transitions has been largely overlooked until recently. just as with bulk phase transformations, complexion transition kinetics can be represented on time temperature transformation (ttt) diagrams. an experimental complexion ttt diagram is presented here for polycrystalline eu doped spinel annealed at 1400–1800.

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Time temperature precipitation diagrams and time temperature embrittlement diagrams have also been used to represent kinetic changes in steels. the ttt diagram for aisi 1080 steel (0.79%c, 0.76%mn) austenitized at 900°c . time temperature transformation for steel. isothermal transformation (it). The kinetics of such complexion transitions has been largely overlooked until recently. just as with bulk phase transformations, complexion transition kinetics can be represented on time temperature transformation (ttt) diagrams. an experimental complexion ttt diagram is presented here for polycrystalline eu doped spinel annealed at 1400–1800. Ttt diagram relates the transformation of austenite to time and temperature conditions. hence, the ttt diagram indicates transformation products as per temperature and also the time needed for complete transformation. in fig 1, curve 1 is transformation begin curve while curve 2 is the transformation end curve. John k. gillham. tment of chemical engineering princeton university, princeton, nj 08544abstracta generalized time temperature transformation (ttt) state diagram for the thermosetting process is presented in which the four physical states encountered (i.e., liquid, rubber, ngelled glass and gelled glass) are related to the time and temperature.

Comments are closed.