Testing 3 Phase Motor Windings

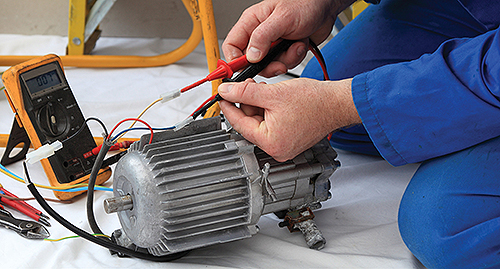

How To Test A 3 Phase Motor Windings With An Ohmmeter Learning The first thing to do before testing the windings of the motor is to remove the links linking terminals w2u2v2 and the disconnect the motor from supply (l1, l2, l3). a multimeter terminals placed across this matrix of terminals will indicate the following readings for a good 3 phase motor: (a) terminals w1w2, u1u2, v1v2 will indicate continuity. How to perform a motor winding resistance test. using a multimeter check the resistance between the three terminals. these terminals are u, v, and w. multimeter to test for resistance (ohms) in three phase motors, the readings between each winding should be around the same. each of the three windings is identical and the resistance should be.

Testing 3 Phase Motor Windings Test your winding condition by testing these connections: t1 to t3. t2 to t3. t1 to t2. the reading should be between 0.3 to 2 ohms. if it is zero, there is a short. if it is over 2 ohms or infinite, there is an open. users can also dry the connector and retest to possibly get more accurate results. Step 3: test each winding with a multimeter. using the red and black probes, start testing each winding of the 3 phase motor. if the multimeter reads between 50 and 200 ohms, it indicates that your winding is in good condition. to ensure a proper check on all internal connections of each phase, use an ohmmeter and check the internal connections. Test your winding condition by testing these connections: t1 to t3. t2 to t3. t1 to t2. the reading should be between 0.3 to 2 ohms. if it is 0, there is a short. if it is over 2 ohms or infinite, there is an open. you can also dry the connector and retest to possibly get more accurate results. check the inserts for burn marks and cables for wear. Check the connection bar for terminal (u, v, and w). for three phase motors, connection type is either star (y) or delta. ac motor winding continuity test. using a multimeter, check the continuity of motor winding from phase to phase ( u to v, v to w , w to u ).each phase to phase must have a continuity if winding is ok.

How To Test 3 Phase Motor With Multimeter Youtube Test your winding condition by testing these connections: t1 to t3. t2 to t3. t1 to t2. the reading should be between 0.3 to 2 ohms. if it is 0, there is a short. if it is over 2 ohms or infinite, there is an open. you can also dry the connector and retest to possibly get more accurate results. check the inserts for burn marks and cables for wear. Check the connection bar for terminal (u, v, and w). for three phase motors, connection type is either star (y) or delta. ac motor winding continuity test. using a multimeter, check the continuity of motor winding from phase to phase ( u to v, v to w , w to u ).each phase to phase must have a continuity if winding is ok. To assess the insulation quality, a megger tests a wire by exposing it to a high dc voltage for a predetermined time. in general, the process of testing a 3 phase motor with a megger is easy: turn off the motor’s power source by flipping the circuit breaker. set the megger to ohms and then check the leads to check electrical continuity. Both phase windings are usually melted open, so the problem is easily detected. among the causes of interphase breakdown are contaminants, tight fit (in the slot), age, mechanical damage, and high voltage spikes. coils that form the poles for each phase are placed on top of each other in all three phase motors. figure 3 is a concentric type.

Testing Windings On 3 Phase Motor To assess the insulation quality, a megger tests a wire by exposing it to a high dc voltage for a predetermined time. in general, the process of testing a 3 phase motor with a megger is easy: turn off the motor’s power source by flipping the circuit breaker. set the megger to ohms and then check the leads to check electrical continuity. Both phase windings are usually melted open, so the problem is easily detected. among the causes of interphase breakdown are contaminants, tight fit (in the slot), age, mechanical damage, and high voltage spikes. coils that form the poles for each phase are placed on top of each other in all three phase motors. figure 3 is a concentric type.

How To Check Windings In A 3 Phase Motor Webmotor Org

Comments are closed.