Plastic Injection Molding In Action

Introduction To Injection Molding The action is inserted into the mold before injection, then unscrewed from the part after the material has set. 5. collapsible core. collapsible core actions are useful for releasing circular undercuts. parts are molded directly around the action, the core of which collapses once the material is set. In addition to custom injection molding, we also provide capabilities in tooling, quality assurance, engineering support, value added services, assembly and kitting, and automation. action plastics was started 40 years ago on a simple principal: know what we are doing and do it well. it is easy to lay claim to words like excellence.

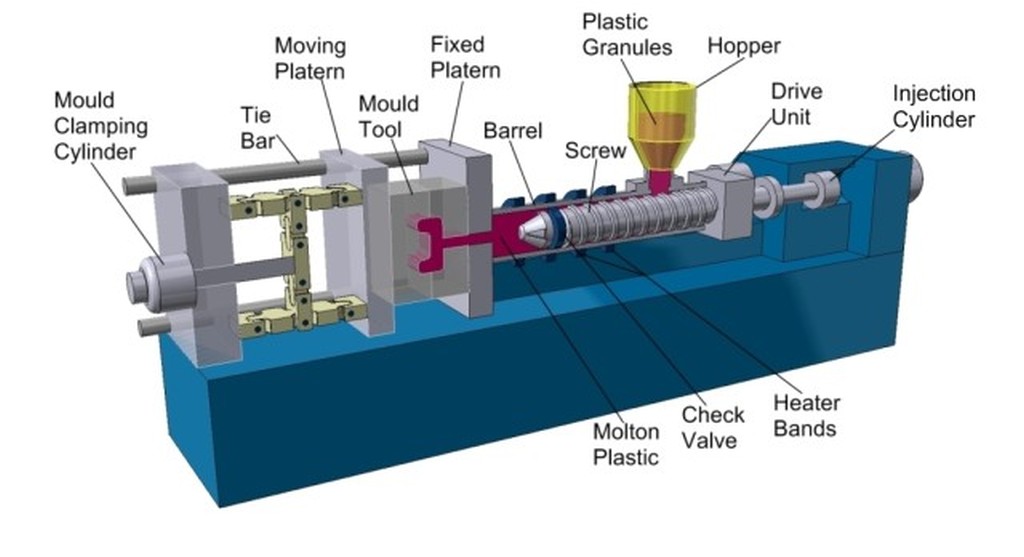

Plastic Injection Molding Definitions And Benefits Of Using It Different types of injection molding side actions. slides create and release external undercut features by collapsing into place via a cam as the tool closes. it then pulls away as the tool opens. lifters create and release internal undercut features. similar to slides, lifters move into place via a cam as the tool closes and move away as the. Our location. 3121 ken o sha industrial ct se, grand rapids, mi 49508. united states. call us: (616) 570 0625. action molding is an innovative grassroots company that has been providing quality made sturdy products with excellent customer service since 2009. Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. in injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. the materials used in injection molding are thermoplastic polymers that can. Injection moulding (u.s. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. injection moulding can be performed with a host of materials mainly including metals (for which the process is called die casting), glasses, elastomers, confections, and most commonly.

Automation In Injection Molding Making The Us Globally Competitive Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. in injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. the materials used in injection molding are thermoplastic polymers that can. Injection moulding (u.s. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. injection moulding can be performed with a host of materials mainly including metals (for which the process is called die casting), glasses, elastomers, confections, and most commonly. This begins the material’s journey. the barrel heats and melts the plastic. friction and barrel heaters melt the pellets at 200 300°c. an internal screw mixes the polymer. the screw injects the molten plastic. the rotating screw provides consistent pressure and speed for complete mold filling. the two mold halves close. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. a wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. the injection molding process requires the use of an injection molding machine, raw plastic material, and a mold.

Comments are closed.