Magnetic Separator To Separate Metal And Others

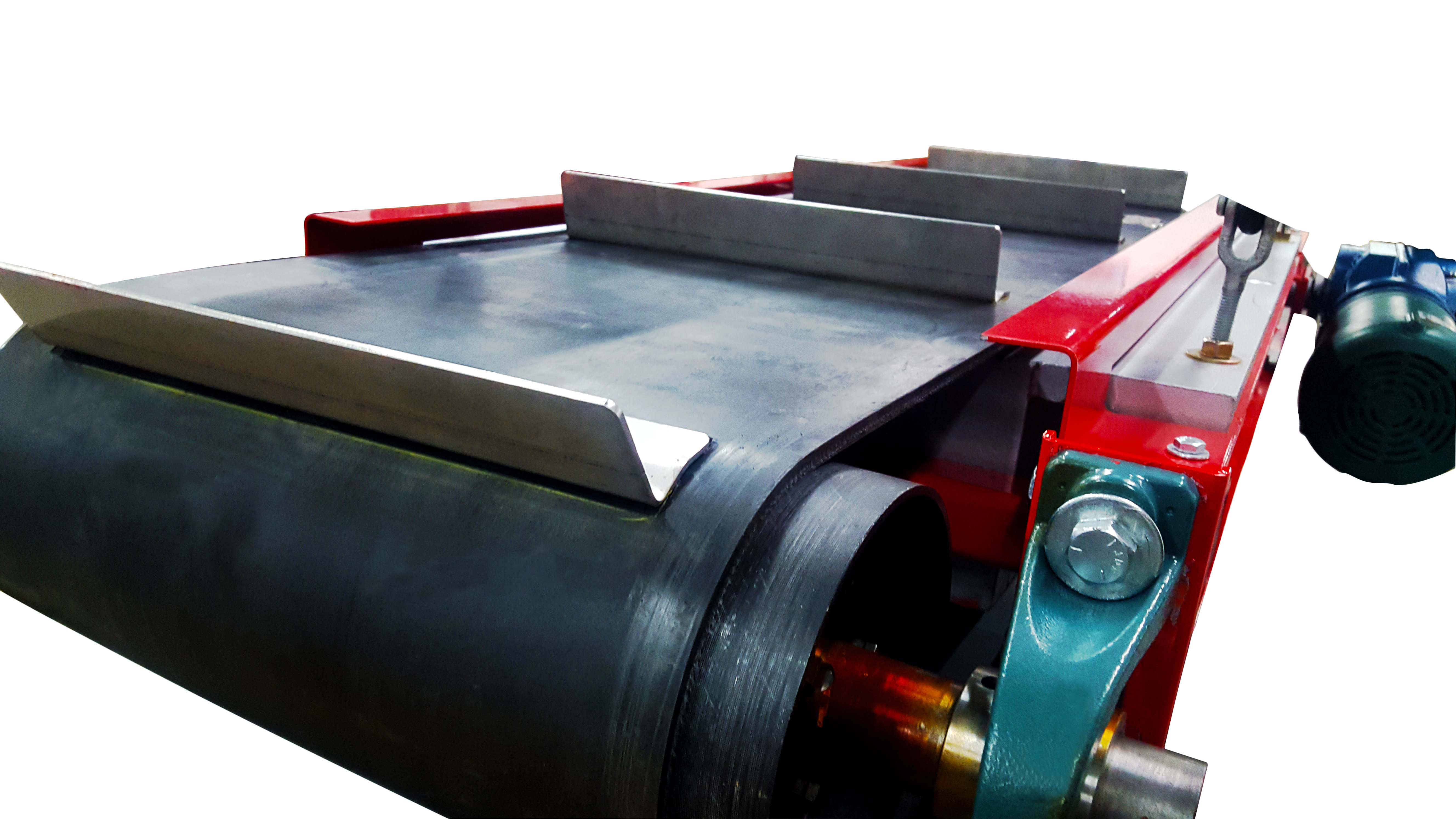

Magnetic Separator Complete Conveyor Solutions Asgco Asgco Magnetic separation is the process of separating components of mixtures by using a magnet to attract magnetic substances. [1] the process that is used for magnetic separation separates non magnetic substances from those which are magnetic. this technique is useful for the select few minerals which are ferromagnetic (iron , nickel , and cobalt. The use of magnetic separators offers multiple benefits. first, they contribute to the quality enhancement of products by eliminating magnetic particles. this results in increased consumer trust and regulatory compliance. second, they protect processing machinery from potential damage caused by metal contaminants, reducing maintenance costs and.

Magnetic Separation Technology For A Recycling Industry Magnetic separators are used to remove metal contaminants from chemical products. this ensures that the products are safe and meet regulatory standards. advantages of magnetic separators: magnetic separators offer several benefits in terms of separation efficiency, cost effectiveness, and ease of operation. let's discuss a few of them:. 3.11.2.5 magnetic separation. magnetic separation is a process where a contaminant is first attached onto a magnetic carrier material (e.g., magnetite), and subsequently, the contaminant laden carrier is separated under a magnetic field. the simplest magnetic separator is a permanent magnet. A magnetic separator applies basic magnetic principles to remove ferrous based and paramagnetic metals from a range of substances including powders, granules, liquids, pellets or pastes. they are usually installed within the product stream at key haccp or inspection points. see our guide to selecting the right magnetic separator. Magnetic separation technology is a physical separation method that uses the differences in magnetism between matter to separate them from each other by different motion behaviors in a non uniform magnetic field. it is highly efficient, green, and environmentally friendly, with little change in the physical and chemical properties of raw materials. magnetic separation technology is commonly.

Magnetic Separation Equipment Magnetic Separators Bunting Magnetics A magnetic separator applies basic magnetic principles to remove ferrous based and paramagnetic metals from a range of substances including powders, granules, liquids, pellets or pastes. they are usually installed within the product stream at key haccp or inspection points. see our guide to selecting the right magnetic separator. Magnetic separation technology is a physical separation method that uses the differences in magnetism between matter to separate them from each other by different motion behaviors in a non uniform magnetic field. it is highly efficient, green, and environmentally friendly, with little change in the physical and chemical properties of raw materials. magnetic separation technology is commonly. Magnetic separation is a physical separation technique that exploits the difference in magnetic properties between materials to achieve separation. it has been applied in diverse fields, including mining, mineral processing, waste management, biomedical research, and environmental remediation. the fundamental principle underlying magnetic. Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores. these devices for separation of strongly magnetic materials employ a variety of mechanical designs. recently developed high gradient magnetic separation devices extend the useful application of magnetic separation to very weakly.

Comments are closed.