Lesson 5 Synchronous Generator Cooling Hydrogen Purging And Charging

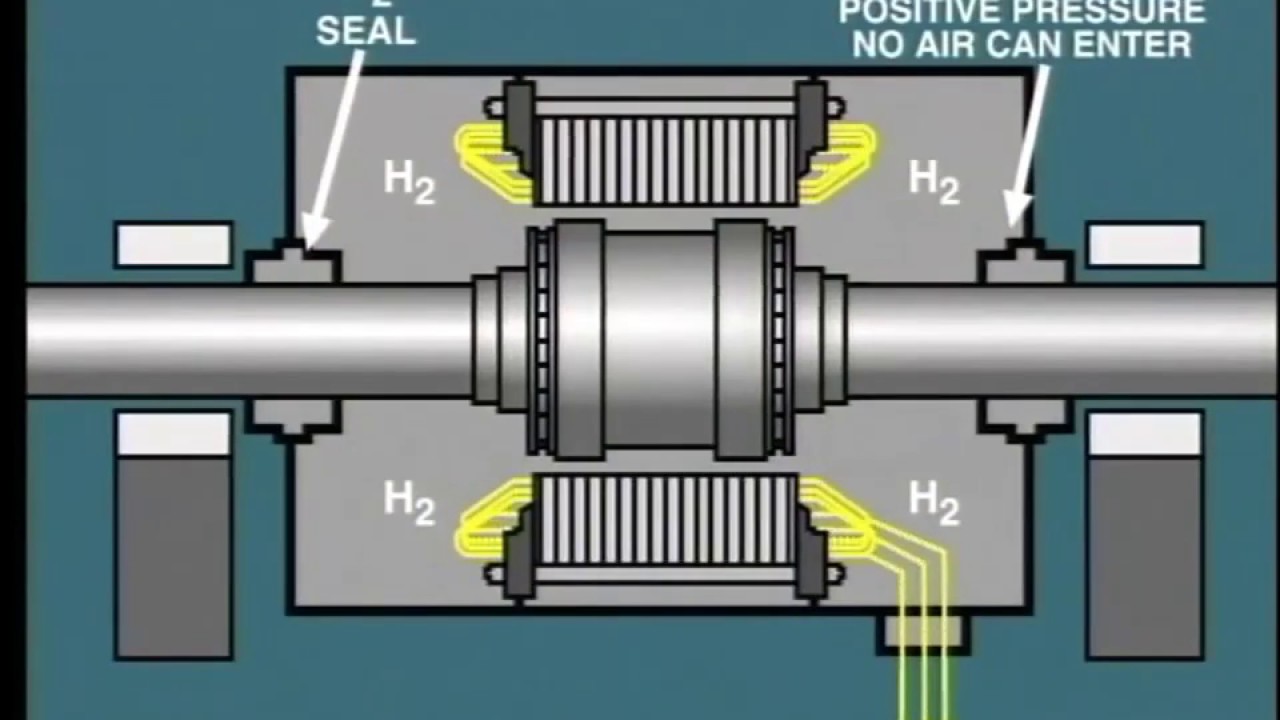

Lesson 5 Synchronous Generator Cooling Hydrogen Purging And Charging Synchronous generator,generator cooling hydrogen,using hydrogen to cool synchronous generator. A hydrogen cooled generator uses "seals" to keep the hydrogen gas inside the generator. the hydrogen seals are on the two shaft "ends" that pass through the generator end shields. oil is typically used as the sealing medium, and is sprayed on the shaft around the entire circumference of the shaft. the "seal oil" is at a higher pressure than the.

Lesson 2 Hydrogen Cooled Synchronous Generator Youtube 98%. 99%. =((0.99*1) (0.01*14.4))*100. because air is 14 times as dense as hydrogen, the density of the fluid in the generator casing rises quickly with air impurity level. as can be seen from the equation, every 1 percent of air contamination is worth about 14% increase in fluid density. increased fluid density means increased windage loss. In the hydrogen cooling of a synchronous generator, hydrogen gas is used for cooling because hydrogen gas has excellent cooling properties. the power loss (i 2 r loss) in the form of heat loss occurs in a generator when the generator delivers power to electrical equipment. the life of the generator depends on how efficient the cooling system it. During maintenance shutdowns, the hydrogen cooling loop in the generator is purged with carbon dioxide. after co 2 concentrations are measured with a densitometer to verify the complete removal of hydrogen, the generator is purged with air, and the maintenance is performed. this purging procedure was used in this incident. During start up and shutdown purging operations. during normal operation, the hydrogen purity is monitored in an 80 to 100% h 2 ss, $ u range to detect air leaks or hydrogen supply problems. during the start up of a hydrogen cooled generator, air in the generator is first displaced with carbon dioxide. after the first purge operation is.

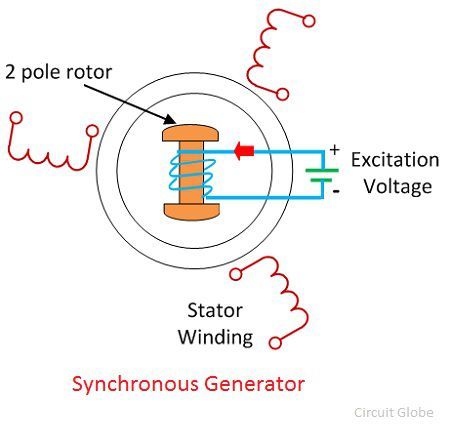

What Is Synchronous Generators Circuit Globe During maintenance shutdowns, the hydrogen cooling loop in the generator is purged with carbon dioxide. after co 2 concentrations are measured with a densitometer to verify the complete removal of hydrogen, the generator is purged with air, and the maintenance is performed. this purging procedure was used in this incident. During start up and shutdown purging operations. during normal operation, the hydrogen purity is monitored in an 80 to 100% h 2 ss, $ u range to detect air leaks or hydrogen supply problems. during the start up of a hydrogen cooled generator, air in the generator is first displaced with carbon dioxide. after the first purge operation is. The patented turbinaltm high flow co2 purge system from airgas, an air liquide company, provides the power industry with the most effective system available for purging hydrogen cooled generators. this system is designed to meet oem specifications for pressure and flow without the need for additional regulators or a flow orifice. Hydrogen was first proposed as a cooling media for rotating electrical machinery in 1925. the first hydrogen cooled machine, a 12.5 mva synchronous condenser, was placed into service in 1928. nearly a decade later, in 1937, the first hydrogen cooled turbo generator was commission by dayton power and light in dayton, ohio – a general electric.

Generator Hydrogen Cooling System Youtube The patented turbinaltm high flow co2 purge system from airgas, an air liquide company, provides the power industry with the most effective system available for purging hydrogen cooled generators. this system is designed to meet oem specifications for pressure and flow without the need for additional regulators or a flow orifice. Hydrogen was first proposed as a cooling media for rotating electrical machinery in 1925. the first hydrogen cooled machine, a 12.5 mva synchronous condenser, was placed into service in 1928. nearly a decade later, in 1937, the first hydrogen cooled turbo generator was commission by dayton power and light in dayton, ohio – a general electric.

Comments are closed.