Lean Singapore Lean Management System Lean Manufacturing

Lean Singapore Lean Management System Lean Manufacturing вђ Bilarasa Lean management or lean is a continuous improvement methodology that focuses on delivering maximum value to the customer by eliminating waste. it first started in manufacturing and was know as lean manufacturing or toyota production system. by eliminating wastes in the process, it shorten cycle time, improve throughput and productivity. Lean is about creating higher value for customers using lesser resources (space, materials, manpower, equipment etc) to create the value. the objective of lean is to eliminate all non value added activities. any activity or process that consumes resources, adds cost or time without creating value is considered waste and becomes the target for.

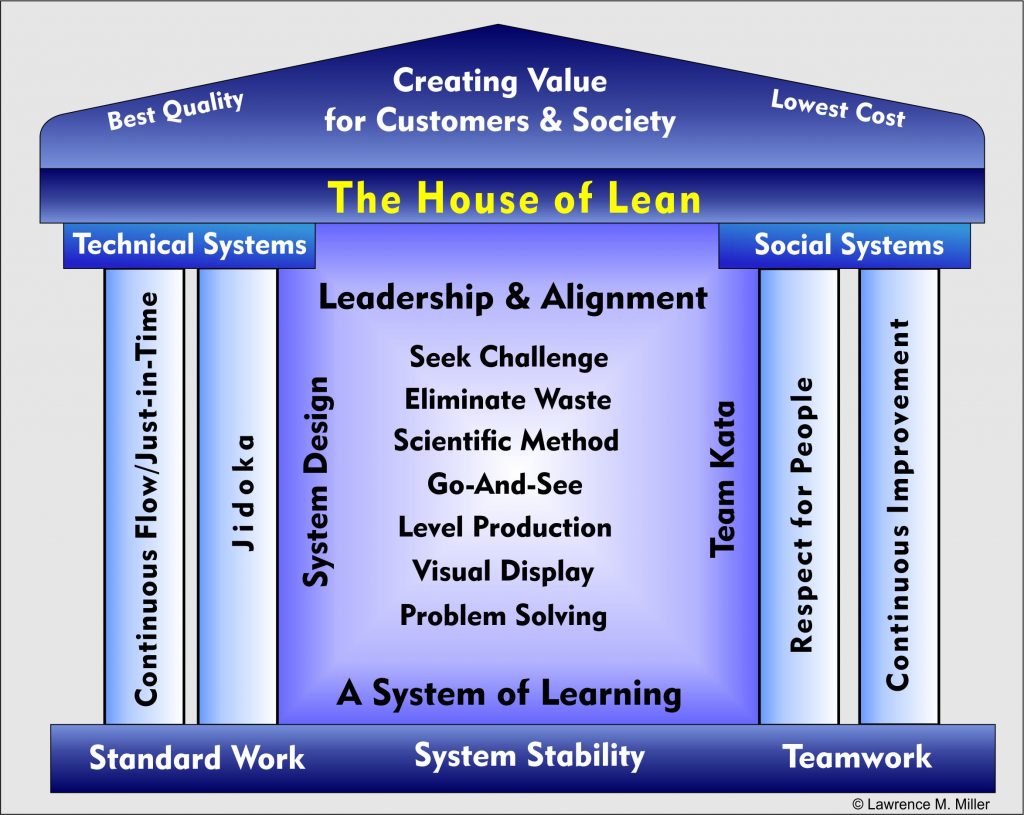

Lean Manufacturing 101 The Why What And How Hms Blog The lean manufacturing methodology is a logical and systematic application that focuses on creating an organisation environment that continuously seek and eliminate the waste. when properly deployed, the organisation will evolve into a learning organisation that continuously lower the water level to surface more challenges. Dcs. scada. v. t. e. lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. it is closely related to another concept called just in time manufacturing (jit manufacturing in short). Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Lean principles. value – specify value from the point of view of the customer. value stream – establish all the process steps in the value stream, and remove any step that does not create value. flow – enable the remaining value creating steps to occur in a very tight and integrated sequence so that the product or service can flow.

What Is Lean Management Lean Management Principles Introduction to lean manufacturing. lean manufacturing is a management approach derived from the toyota production system, devised in japan after world war ii. it aims to maximize value for the customer by eliminating waste, meaning it seeks to optimize processes by using fewer resources and focusing on what is essential to meet customer demands. Lean principles. value – specify value from the point of view of the customer. value stream – establish all the process steps in the value stream, and remove any step that does not create value. flow – enable the remaining value creating steps to occur in a very tight and integrated sequence so that the product or service can flow. Next intake (s)'s training period. (click on the dates to view its schedules) registration status. implement lean manufacturing (40 hours) tgs 2018502730. 19 aug 2024 7 oct 2024. the aug 2024 intake is postponed. we will publish a new schedule soon. sign up now. Lean is a continuous improvement methodology that focused on delivering maximum value to the customer by eliminating wastes. the purpose of lean management system is to create a culture of sustained continuous improvement. the aim of this course is to share the elements of the lean management system that is key to increase business performance.

Comments are closed.