Lean Manufacturing 101 The Why What And How Hms Blog

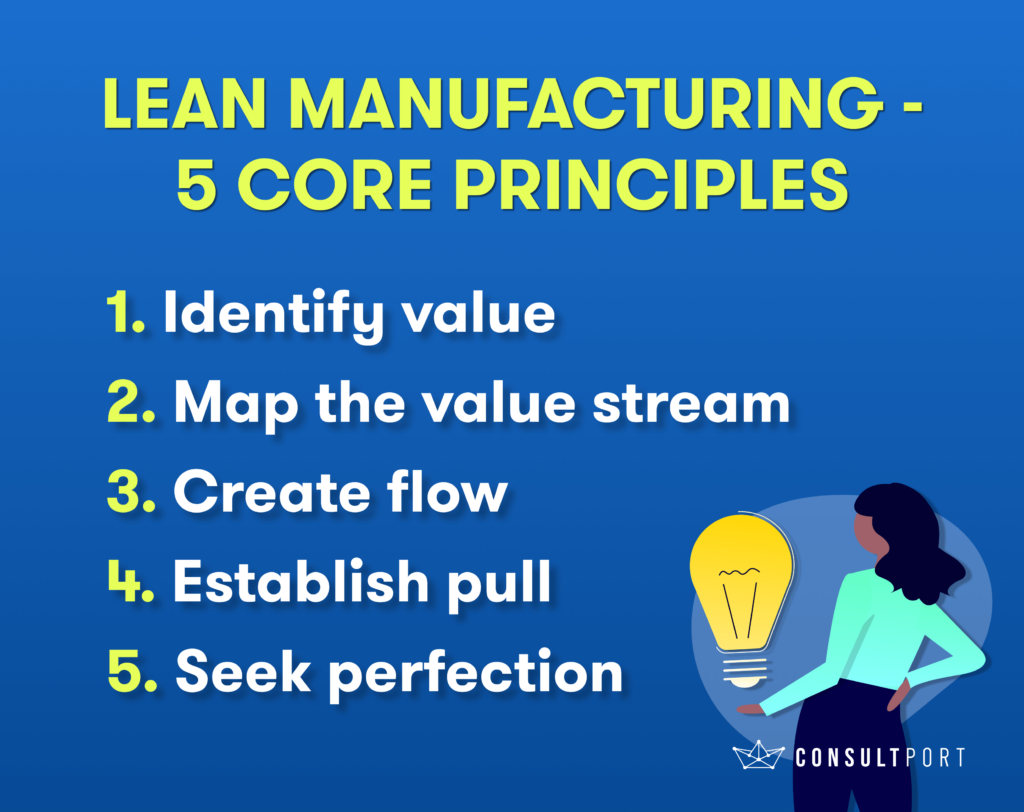

Lean Manufacturing 101 The Why What And How Hms Blog The benefits of lean manufacturing. here are a few common benefits that you stand to reap by introducing lean manufacturing into your business: 1. waste minimization lean manufacturing can efficiently minimize waste within a production facility. this is probably the most significant advantage of lean manufacturing. The five principles of lean manufacturing – value, value stream, flow, pull, and perfection – provide a powerful framework for improving efficiency, reducing waste, and delivering superior value to customers. while each principle is important in its own right, they are most effective when implemented together as an integrated system.

Lean Manufacturing 101 The Why What And How Hms Blog The core of toyota’s business philosophy and culture, on which “lean” is based. its two main pillars are just in time and jidoka (ensuring that quality problems are not passed from part of a process to the next). a third, central pillar is the people pillar, ensuring the respect for people in any process improvement. Sometimes referred to as 5s or five s, it lays out a system for a project (or workplace) to become organized and lean, more specifically, 5s is based around five japanese terms (seiri, seiton, seiso, seiketsu, and shitsuke). in english, we translate them to sort, set in order, shine, standardize, and sustain. let's define each one:. Lean principles provide a framework. lean thinking is comprised of five fundamental principles that provide a framework for creating an efficient organization: specify value – end use customer view. identify value stream – activities that create value. flow – make value flow. pull – respond to customer demand. perfection – zero waste. Benefits of lean manufacturing. lean manufacturing has gained such popularity for a reason—it works. more specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. lean manufacturing also results in improved customer service, higher quality.

How To Implement Lean Manufacturing Principles Techniques And Lean principles provide a framework. lean thinking is comprised of five fundamental principles that provide a framework for creating an efficient organization: specify value – end use customer view. identify value stream – activities that create value. flow – make value flow. pull – respond to customer demand. perfection – zero waste. Benefits of lean manufacturing. lean manufacturing has gained such popularity for a reason—it works. more specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. lean manufacturing also results in improved customer service, higher quality. This means making things efficient, faster, more consistent, and producing at a higher level of precision. lean manufacturing can be used to design a future proof factory that gives you a competitive edge over the others in your market. one of the biggest focuses in lean manufacturing is eliminating waste during the process. Lean manufacturing is about working smart and not wasting anything. back in the 1950s, toyota started this concept, and it means they were really good at making cars without wasting time, materials, or money. today, many companies follow these ideas to improve their work.

Lean Manufacturing 5 Core Principles Explained With Examples This means making things efficient, faster, more consistent, and producing at a higher level of precision. lean manufacturing can be used to design a future proof factory that gives you a competitive edge over the others in your market. one of the biggest focuses in lean manufacturing is eliminating waste during the process. Lean manufacturing is about working smart and not wasting anything. back in the 1950s, toyota started this concept, and it means they were really good at making cars without wasting time, materials, or money. today, many companies follow these ideas to improve their work.

Comments are closed.