Injection Molding In Action

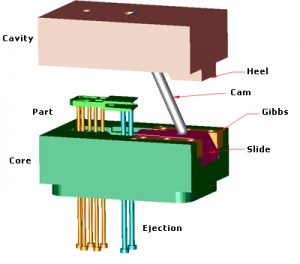

Introduction To Injection Molding Different types of injection molding side actions. slides create and release external undercut features by collapsing into place via a cam as the tool closes. it then pulls away as the tool opens. lifters create and release internal undercut features. similar to slides, lifters move into place via a cam as the tool closes and move away as the. This is an animation of a basic injection mold slide action. the action, tooling, and part are cut away for reference. for the full story click here: https:.

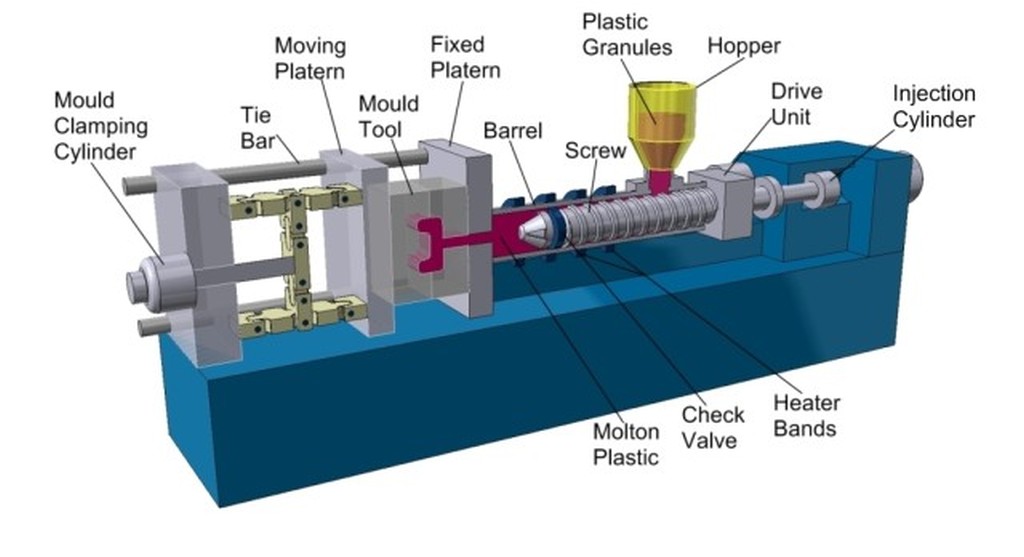

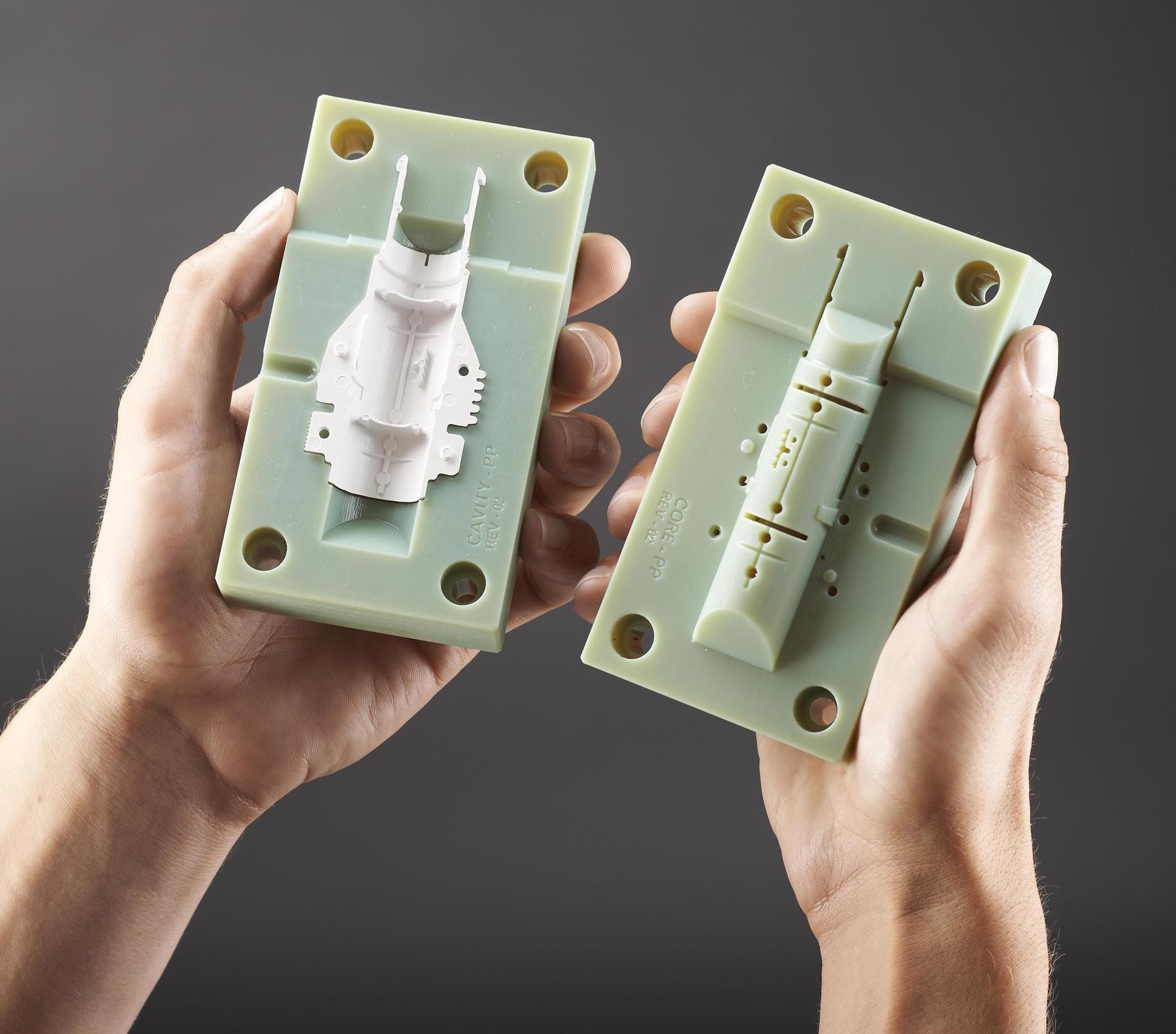

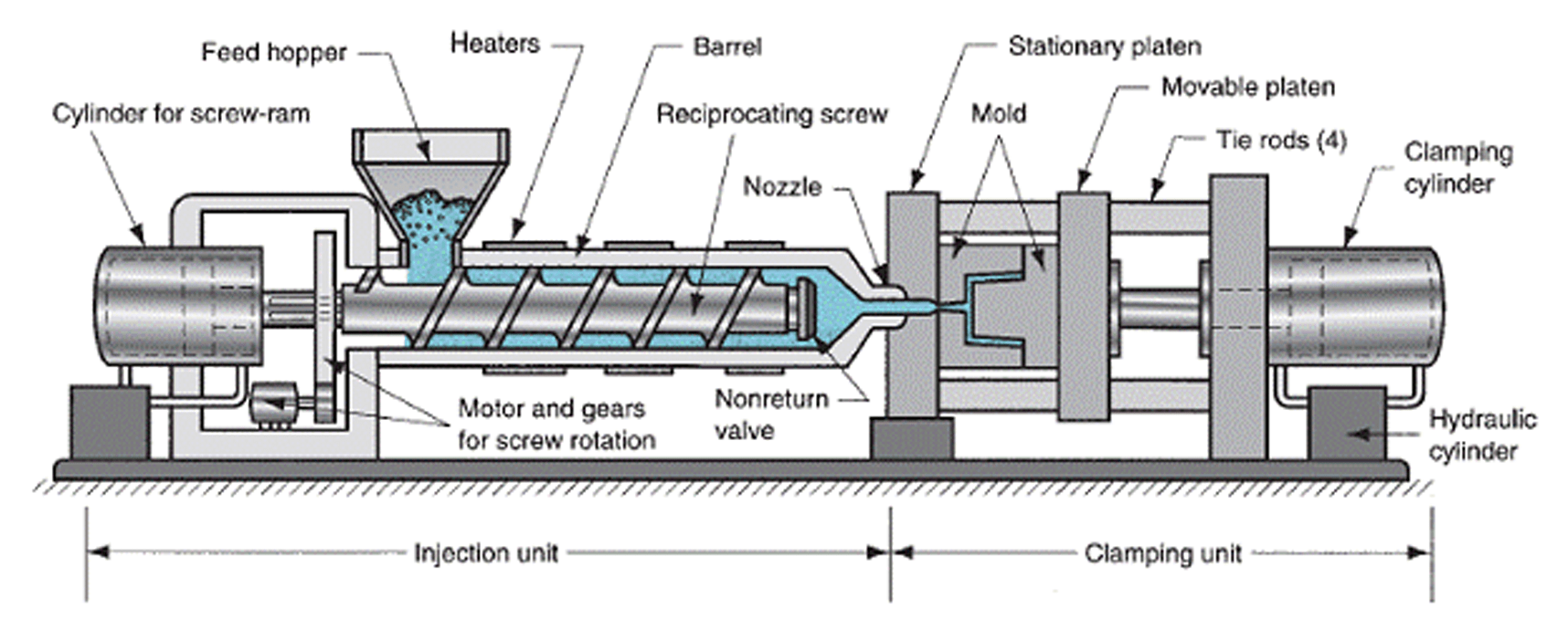

Plastic Injection Molding Terminology Xcentric Mold Engineering The action is inserted into the mold before injection, then unscrewed from the part after the material has set. 5. collapsible core. collapsible core actions are useful for releasing circular undercuts. parts are molded directly around the action, the core of which collapses once the material is set. Discover the process of injection molding, its applications, and how it works in this informative video. Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. in injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. the materials used in injection molding are thermoplastic polymers that can. Injection molding side action overcomes this limitation by employing a cam driven mechanism that withdraws the mold surfaces, allowing safe part ejection. however, the use of side actions requires careful consideration. after molding the part, the side actions must be manually or automatically removed to facilitate part ejection.

Revolutionizing The Injection Molding Process Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. in injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. the materials used in injection molding are thermoplastic polymers that can. Injection molding side action overcomes this limitation by employing a cam driven mechanism that withdraws the mold surfaces, allowing safe part ejection. however, the use of side actions requires careful consideration. after molding the part, the side actions must be manually or automatically removed to facilitate part ejection. Injection mold side actions, often termed inserts or features, play a pivotal role in overcoming the limitations of traditional molding techniques. these additions to the mold enable the creation of undercut geometries, which are essential for intricate part designs. unlike straight pull molds that operate by separating the mold halves, side. Action molding is an innovative grassroots company that has been providing quality made sturdy products with excellent customer service since 2009. we are based in west michigan and operate a 24 5 molding facility that is capable of running 24 7 for seasonal needs. what sets us apart from the competition is our quick delivery and customer service.

Injection Molding Process Xcentric Mold Engineering Injection mold side actions, often termed inserts or features, play a pivotal role in overcoming the limitations of traditional molding techniques. these additions to the mold enable the creation of undercut geometries, which are essential for intricate part designs. unlike straight pull molds that operate by separating the mold halves, side. Action molding is an innovative grassroots company that has been providing quality made sturdy products with excellent customer service since 2009. we are based in west michigan and operate a 24 5 molding facility that is capable of running 24 7 for seasonal needs. what sets us apart from the competition is our quick delivery and customer service.

Comments are closed.