How To Pick A Cooling Tower Comparing Open And Closed Loop Towers

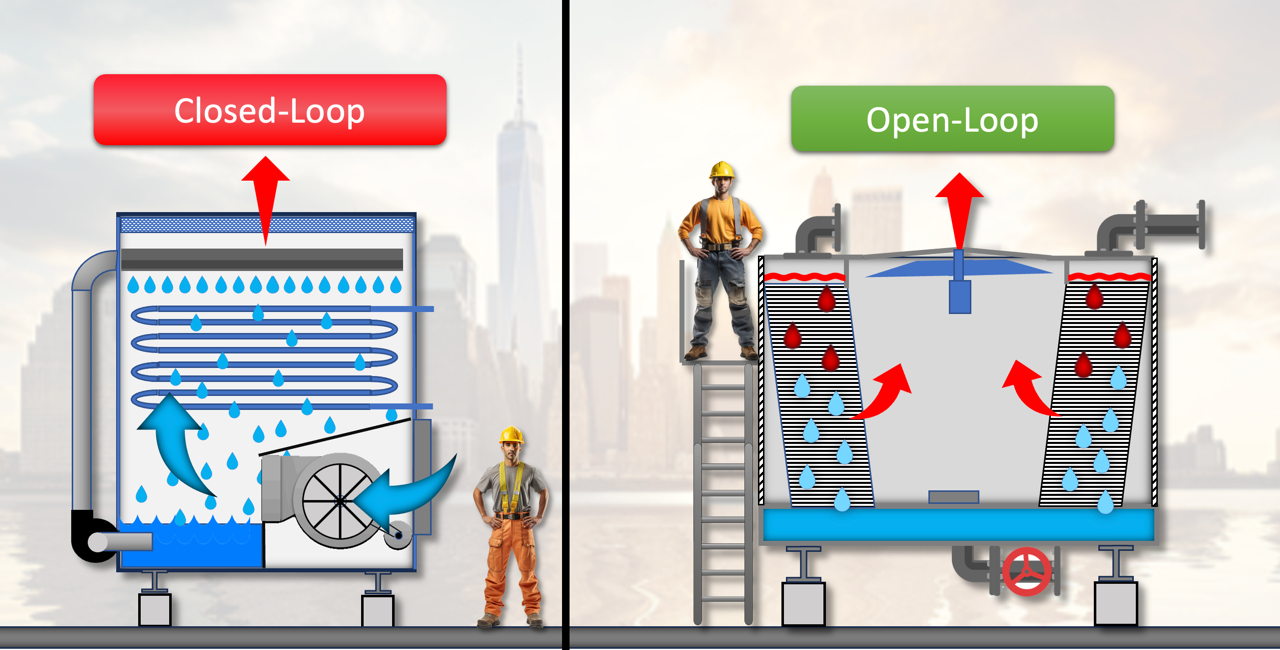

How To Pick A Cooling Tower Comparing Open And Closed Loop Towers When comparing a closed cooling tower’s cost to that of an open cooling tower with a plate and frame heat exchanger, the closed tower tends to have a higher first cost unless you look at the complete cooling tower system with adjacent components. this is because one must remember that open cooling towers often require filtration equipment and. Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger.

Closed Circuit Vs Open Circuit Cooling Towers Mep Academy Different types of closed circuit cooling tower systems. another closed circuit cooling tower system involves a separate heat exchanger package along with an open cooling tower. the fluid on the hot side of the heat exchanger also never makes direct contact with the air. this allows the heat exchanger to be put inside, protected from the. A simpler system. a closed circuit cooling tower can be an alternative to a system composed by an open circuit cooling tower and a heat exchanger. this leads to some advantage: easier plant layout. reduced footprint. higher thermal efficiency. cooling tower: operation and use. 2. lower cooling tower approach: with an open loop cooling tower, a lower approach can be achieved easily. it must be noted that in an open loop cooling tower we need to count two approaches one with the cooling tower and another with the heat exchanger. in the case of the lower approach, the open loop cooling tower shall be beneficial. 3. Cooling towers play a critical role in maintaining the temperature of industrial and commercial operations. but understanding the different types of cooling towers, their functions, and their benefits can be confusing. in this post, we’ll explore the intricacies of open loop and closed loop cooling towers to help building managers and industrial operators make informed […].

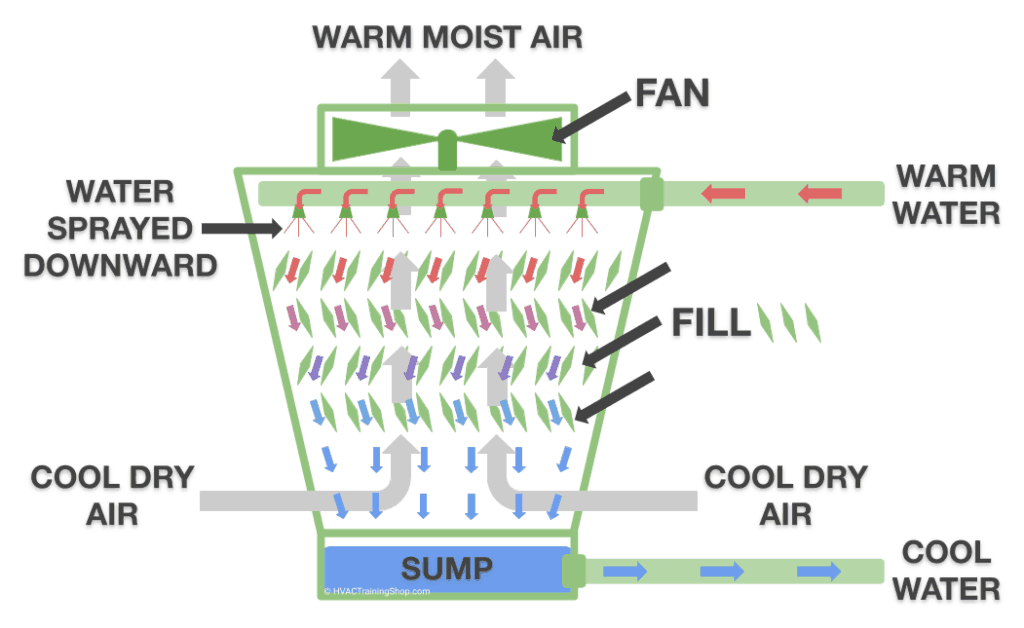

Cooling Tower Open Loop Vs Closed Loop 2. lower cooling tower approach: with an open loop cooling tower, a lower approach can be achieved easily. it must be noted that in an open loop cooling tower we need to count two approaches one with the cooling tower and another with the heat exchanger. in the case of the lower approach, the open loop cooling tower shall be beneficial. 3. Cooling towers play a critical role in maintaining the temperature of industrial and commercial operations. but understanding the different types of cooling towers, their functions, and their benefits can be confusing. in this post, we’ll explore the intricacies of open loop and closed loop cooling towers to help building managers and industrial operators make informed […]. How to pick a cooling tower: crossflow versus counterflow. cooling towers for hvac systems come in either crossflow or counterflow configurations. this is defined by the way the water meets the heat transfer surface, more commonly known as the “fill” surface. crossflow cooling towers distribute the hot water…. read more →. In open loop and closed loop cooling towers, the fill media facilitates the contact between air and the water surface. this media helps the water spread into thin, flowing layers, maximizing the surface area exposed to the air flow. fill media is typically made from materials such as polypropylene, wood, or pvc.

Comments are closed.