How Do The Slider Work In Injection Mold

The Slider For Plastic Injection Mold Ecomolding Copyright reserved by ecomolding due to the special requirements of a product, the mold release direction of a particular part may not be con. How do injection molding lifters work? injection molding lifters consist of a blade like or pin like lifting mechanism, an ejector plate, and a retainer plate. there’s also a block like locking mechanism. unlike a slider, which pushes the injection molded part to one side, a lifter pushes the part upward and at an angle.

How Do The Sliders Slide Work In Plastic Injection Mold Youtube The mold opening action of the injection molding machine is leveraged to make the guide block and the slide move relatively, and surface b engages with the slide to make it move in two directions – the mold opening direction and the horizontal direction, so that it disengages with the undercut. the guide block acts as an angle pin when the. Injection molding lifters are movable components within a mold that enable the creation of undercuts or features that require an angle relative to the direction of the mold’s opening and closing. they play a crucial role in injection molding, allowing the production of complex parts with undercuts on both the exterior and interior surfaces. The injection molding slides are activated after the injection mold machine opens up. after the molten plastic product has solidified, it is ready to be removed as a complete plastic product. the slider usually has a hydraulic system that pushes it in a lateral direction. the mechanism for this mold slider is set up so that the lateral sliding. An injection molding slider, also known simply as a slider, is a movable part within the injection mold that facilitates the creation of undercuts, complex geometries, and features that cannot be formed using a standard mold. sliders are essential for producing parts with overhangs, side holes, thread, or other intricate details that would.

How Do The Slider Work In Injection Mold Youtube The injection molding slides are activated after the injection mold machine opens up. after the molten plastic product has solidified, it is ready to be removed as a complete plastic product. the slider usually has a hydraulic system that pushes it in a lateral direction. the mechanism for this mold slider is set up so that the lateral sliding. An injection molding slider, also known simply as a slider, is a movable part within the injection mold that facilitates the creation of undercuts, complex geometries, and features that cannot be formed using a standard mold. sliders are essential for producing parts with overhangs, side holes, thread, or other intricate details that would. Designing an effective injection molding slider is a crucial part of the mold creation process. these slides play a pivotal role in enabling the production of complex parts with undercuts, threads, and intricate features. to help you navigate this process, here’s a step by step guide for designing an injection slide mold: 1. In a plastic injection mold, the mold opening action is leveraged to create a relative movement trend between the angle pin and the slide, so that the slide moves in two directions – the mold opening direction and the horizontal direction – to release it from the undercut. see the diagrams below:.

The Slide In Plastic Injection Mold Designing an effective injection molding slider is a crucial part of the mold creation process. these slides play a pivotal role in enabling the production of complex parts with undercuts, threads, and intricate features. to help you navigate this process, here’s a step by step guide for designing an injection slide mold: 1. In a plastic injection mold, the mold opening action is leveraged to create a relative movement trend between the angle pin and the slide, so that the slide moves in two directions – the mold opening direction and the horizontal direction – to release it from the undercut. see the diagrams below:.

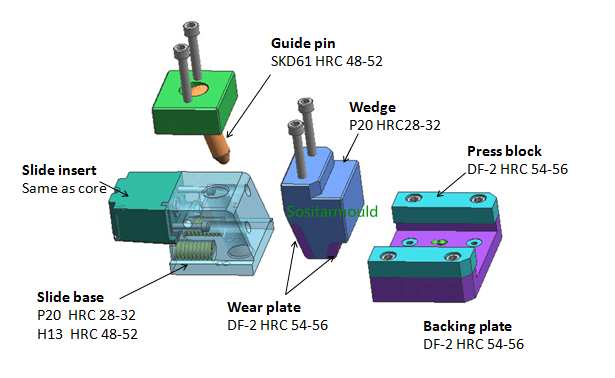

Injection Mold Slider Design

Comments are closed.