How Cooling Towers Work

Cooling Towers Explained How Does A Cooling Tower Work Learn about the different types and principles of cooling towers, how they cool down water and air, and how they work with thermal power plants. see diagrams, pictures and examples of crossflow, counterflow, natural draft, induced draft and forced draft cooling towers. A typical evaporative, forced draft open loop cooling tower rejecting heat from the condenser water loop of an industrial chiller unit. a cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream, to a lower temperature.

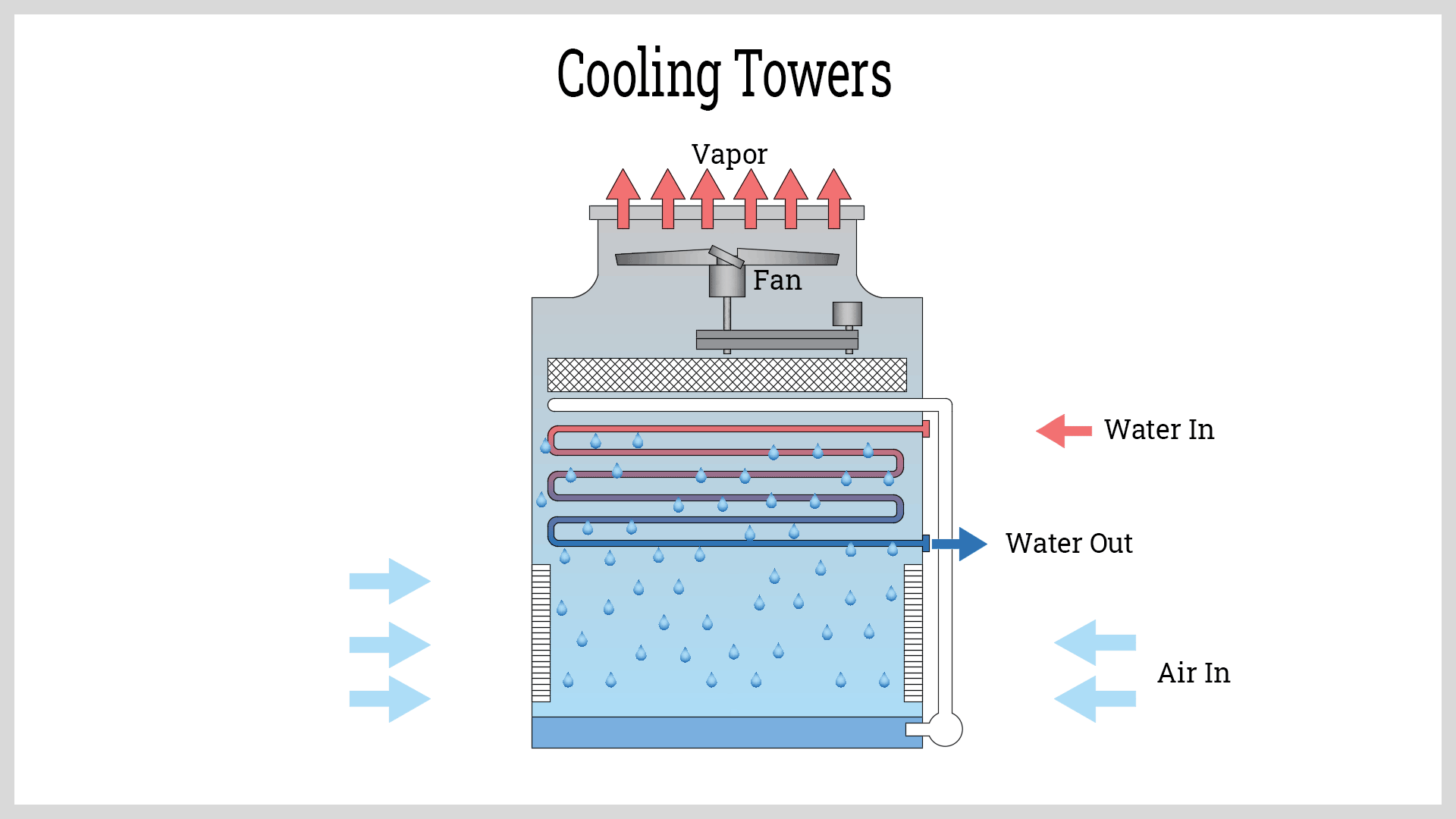

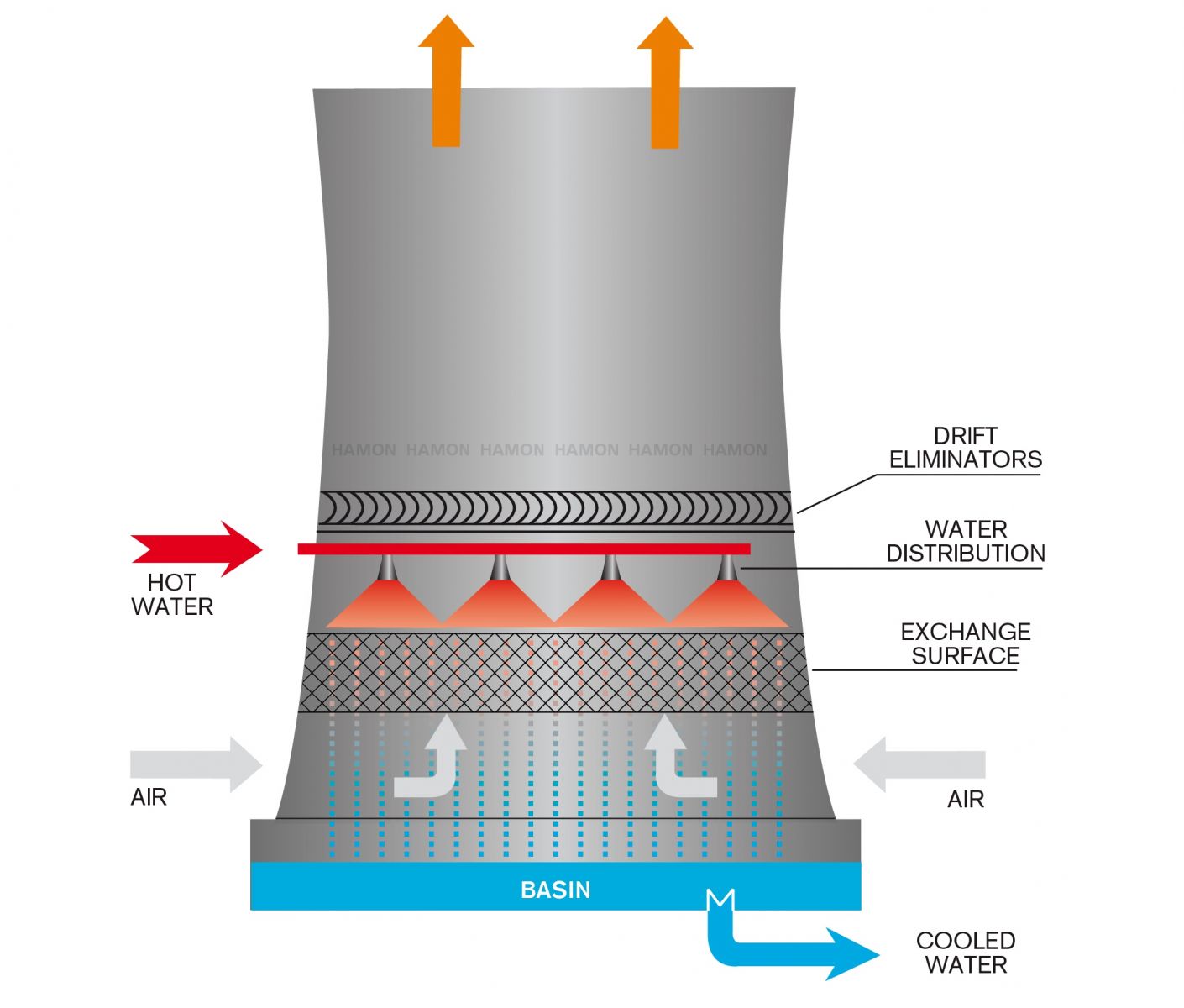

Cooling Towers Explained How Does A Cooling Tower Work Learn what a cooling tower is, how it works, and why it is needed for industrial and hvac processes. compare different types of cooling towers and the best materials for them. Learn about the history, types and functions of cooling towers, which are structures that recycle water for various cooling processes. find out how natural and induced draft cooling towers use natural or artificial airflow to cool hot water and release steam. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. 1. what is a cooling tower 2. how do cooling towers work explanation 3. cooling tower working priciple 4. what are cooling towers used for 5. cooling tower applications 6. types of cooling tower systems 7. how cross flow cooling towers work 8. how counter flow cooling towers work 9. how forced draft & induced draft cooling towers work 10.

Cooling Towers Components Working Principles And Lifespan A Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. 1. what is a cooling tower 2. how do cooling towers work explanation 3. cooling tower working priciple 4. what are cooling towers used for 5. cooling tower applications 6. types of cooling tower systems 7. how cross flow cooling towers work 8. how counter flow cooling towers work 9. how forced draft & induced draft cooling towers work 10. The cold water basin is located at the bottom of the tower, and it receives the cooled water that flows down through the tower and fill. basin dimension (m): 84.6 x 17. material of basin: rcc. chemical dosing is done in cooling tower basin for following purposes: sulphuric acid: to maintain ph. In this video we look at how a cooling tower works. we take an overview of each main component with real world examples, colour illustrations and 3d models t.

How Cooling Towers Work Diagram Pictures Principles Sara Cooling The cold water basin is located at the bottom of the tower, and it receives the cooled water that flows down through the tower and fill. basin dimension (m): 84.6 x 17. material of basin: rcc. chemical dosing is done in cooling tower basin for following purposes: sulphuric acid: to maintain ph. In this video we look at how a cooling tower works. we take an overview of each main component with real world examples, colour illustrations and 3d models t.

Comments are closed.