Five Revolutions Into The Lean Journey What S Next Lean Enterprise

Five Revolutions Into The Lean Journey What S Next Lean Enterprise I would argue that we’ve been through five different revolutions in our understanding of lean, with more to follow. the first one focused on just in time: examining time, understanding the need for speed, and recognizing the efficiency improvements that come from focusing on doing everything quickly for customers when they need it – value. Five revolutions into the lean journey: what's next? – daniel jones says the current pandemic serves as an opportunity for us to rethink the world of enterprise and explains five different revolutions of lean.

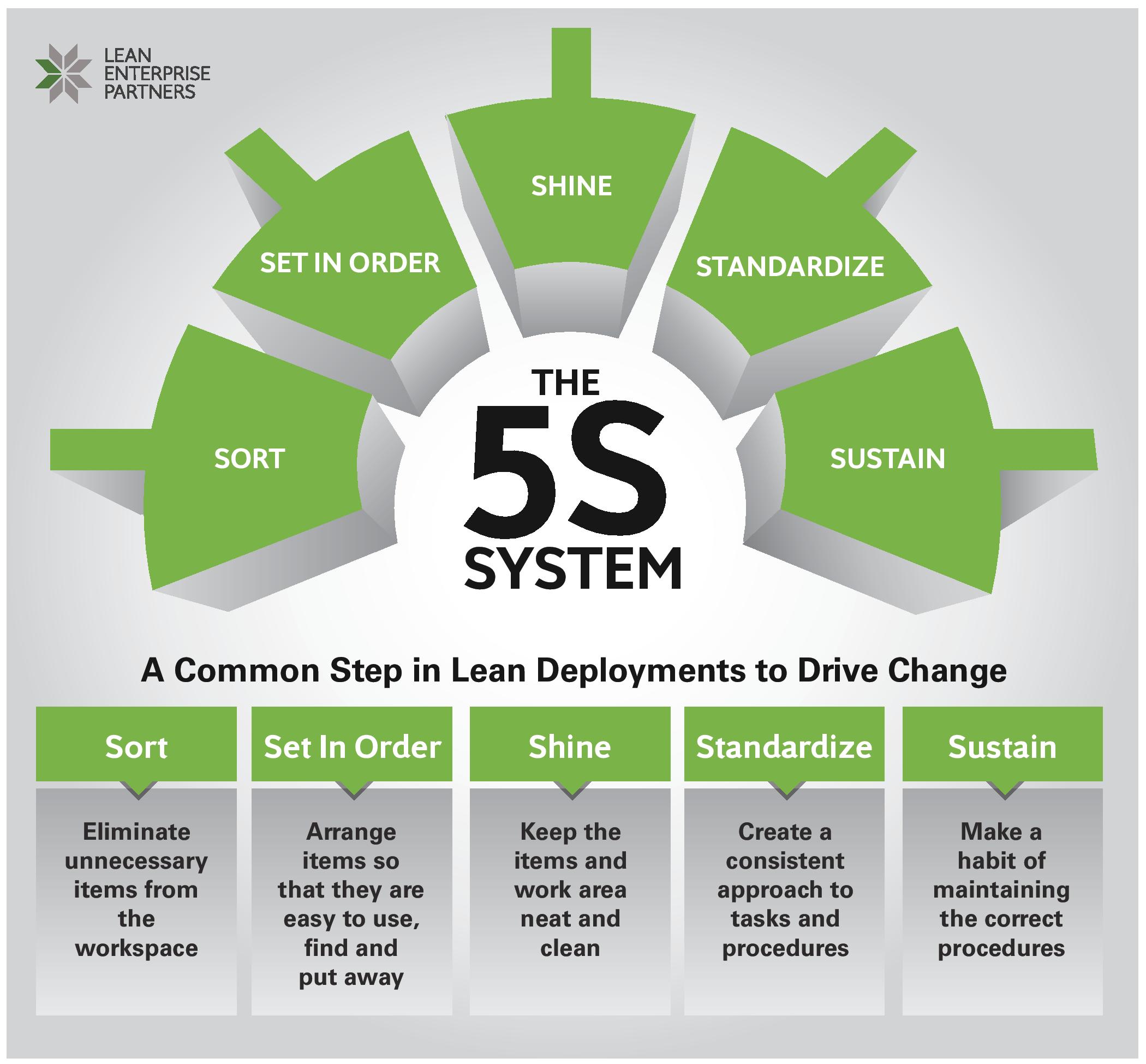

Lean Enterprise Partners Blog Fundamentally, lean seeks to refine a company’s basic systems to meet changing customer needs more effectively. the four disciplines of lean management, described in more detail in “the organization that renews itself: lasting value from lean management” (page 8), are supported by a set of tools and techniques that shape day to day work. Restaurants. “lean techniques seek to improve product and service quality while simultaneously reducing waste and labor costs. for food service operators, the additional trick is to link such improvements to customer loyalty.”. john r. mcpherson and adrian v. mitchell, “ lean cuisine,” mckinsey quarterly, february 2005. 2. The lean transformation framework is a proven, systematic approach to resolving problems at every level of the enterprise, from executive level strategy to frontline operations. whether you lead an established organization or a startup, you can use the framework to address any troubling issue by answering its five questions. While many plants have used value stream thinking and practices such as current and future state mapping, parker hannifin corporation's new haven, in, plant has created a value stream culture centered on autonomy, entrepreneurialism, and lean principles. the change started after months of lengthy discussions among functional leaders, who ultimately determined the best way to remain.

How To Begin Your Lean Journey The lean transformation framework is a proven, systematic approach to resolving problems at every level of the enterprise, from executive level strategy to frontline operations. whether you lead an established organization or a startup, you can use the framework to address any troubling issue by answering its five questions. While many plants have used value stream thinking and practices such as current and future state mapping, parker hannifin corporation's new haven, in, plant has created a value stream culture centered on autonomy, entrepreneurialism, and lean principles. the change started after months of lengthy discussions among functional leaders, who ultimately determined the best way to remain. Key roles of a lean leader. although leaders at the top of the organization wear many hats and are required to fulfill countless duties, within a lean enterprise, only four are critical to making the new culture stick: removing ambiguity by teaching the organization to structure and standardize its activities;. Five years into their lean journey tesco had already grown sales through better product availability, saved cash from less inventories, cuts cost from improved store and warehouse productivity and less wastage and saved £400m by postponing their warehouse building programme by four years. they then realised their rapid response supply chains.

Five Phases Of Lean Roadmap вђ A Thousand Step Journey вђ Site Title Key roles of a lean leader. although leaders at the top of the organization wear many hats and are required to fulfill countless duties, within a lean enterprise, only four are critical to making the new culture stick: removing ambiguity by teaching the organization to structure and standardize its activities;. Five years into their lean journey tesco had already grown sales through better product availability, saved cash from less inventories, cuts cost from improved store and warehouse productivity and less wastage and saved £400m by postponing their warehouse building programme by four years. they then realised their rapid response supply chains.

The Five Steps Of Lean Implementation Lean Enterprise Institute

Comments are closed.