99 Toyota Sienna Elx 3 0 Engine Cooler Diagram

1999 Toyota Sienna Engine Diagram Toyota sienna service manual engine 2gr fe engine control system engine assembly. components. removal. 1. discharge fuel system pressure (see page fu 13) 2. discharge refrigerant from refrigeration system (see page ac 172) 3. remove battery. (a) disconnect the negative battery terminal. (b) disconnect the positive battery terminal. The return coolant flow is controlled by the thermostat located at the inlet (bottom hose) to the engine. this allows the thermostat to keep the water in the radiator moving faster or slower depending on the coolant temp. this inlet is also where the water pump is located. if you have a 4wd 5vz fe, yer oil cooler circuit comes off of the water.

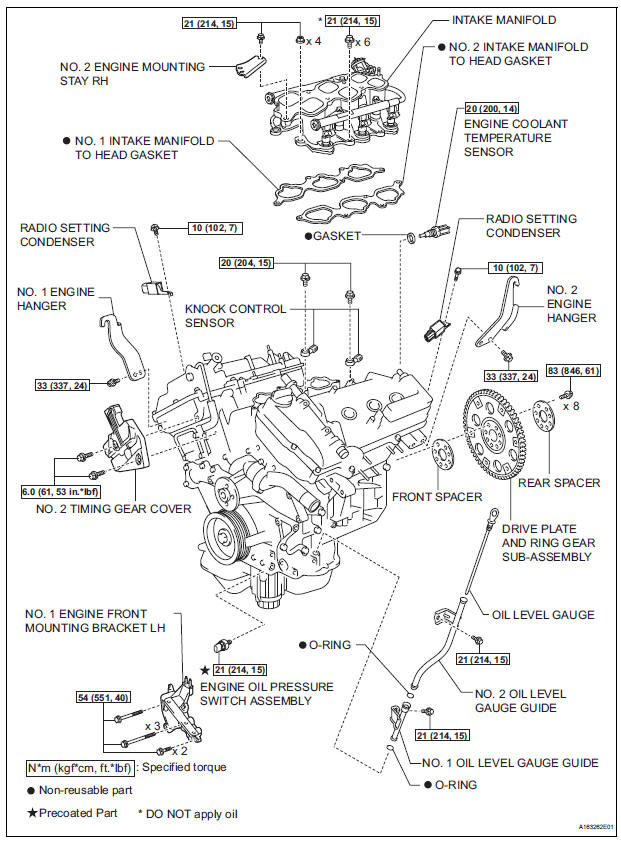

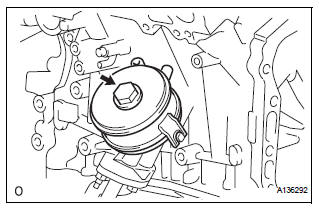

Toyota Sienna Service Manual Installation Engine Oil Cooler 2gr Fe Page 157 relay contact on condition: bm terminal voltage is 4.0 v or above. wiring diagram skid control ecu f8 fusible engine room r b no. 2 engine room j b no. 2 link block 60a abs engine room j b no. 2 fl main gnd1 gnd2 battery f13445 2001 sienna (rm787u) author : date : page 158 check and repair harness or connector. if the same code is. I just purchased a 2013 toyota sienna le and realized that not all of the 2013 models came with towing capacity. the booklet says it can tow up to 3500lbs, but i am hearing that the le's may not have a transmission engine oil cooler. we tow a popup that weights about 3,000lbs fully loaded and. Our most popular manual is the 2001 toyota sienna service and repair manual (rm787u) . this (like all of our manuals) is available to download for free in pdf format. how to download a toyota sienna repair manual (for any year) these sienna manuals have been provided by our users, so we can’t guarantee completeness. Toyota sienna service manual engine 2gr fe engine control system engine unit reassembly. 1. install straight pin. (a) using a plastic hammer, tap in new straight pins to the cylinder block. standard protrusion. 2. install stud bolt. (a) using e8 and e10 "torx" sockets, install the stud bolts. torque: 10 n*m (102 kgf*cm, 7 ft.*lbf) for.

Comments are closed.