50 Bar To 700 Bar Hydrogen Fueling Stations For Vehicles

50 Bar To 700 Bar Hydrogen Fueling Stations For Vehicles Youtube The station uses a 700 bar pressure fill system, allowing hydrogen fuel to be dispensed into onboard storage for long range vehicles, such as the nikola hydrogen fuel cell electric class 8 truck. “it is inspiring to witness the vision of a hydrogen powered future coming to life with the opening of this refueling station in the greater toronto. Phoenix –january 18, 2023 — nikola corporation (nasdaq: nkla), a global leader in zero emission transportation and energy supply and infrastructure solutions, announced that it has developed an innovative, heavy duty, 700 bar (10,000 psi) hydrogen mobile fueler capable of direct fueling hydrogen fuel cell electric vehicles (fcevs).

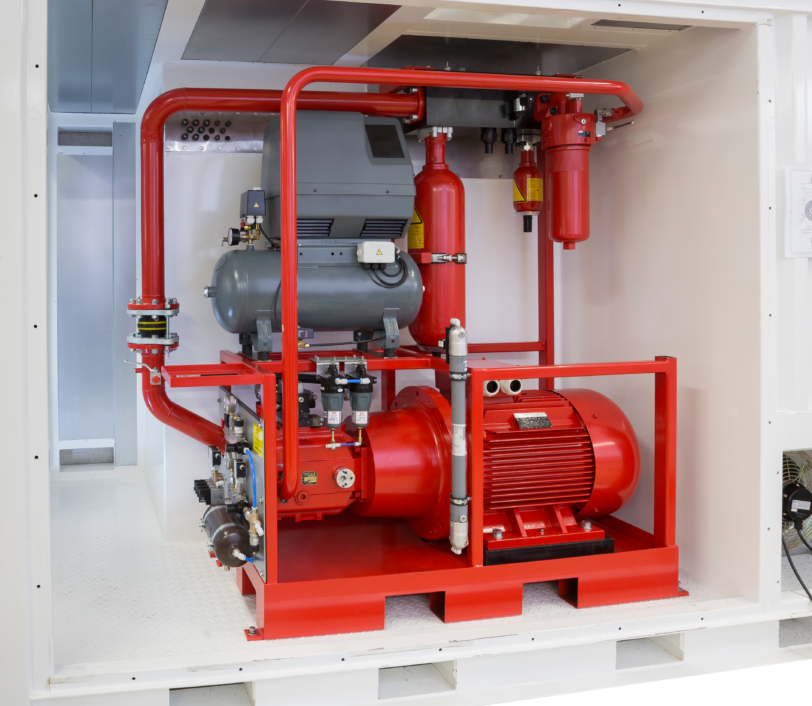

Hydrogen Refueling Station 700 Bar Hyfindr Teesing's patent on hydrogen filling technology. vehicles currently refuel hydrogen at a pressure of about 350 bar. it is interesting to increase that pressure to 700 bar because it increases vehicle filling speed and range. this places quite a few demands on the equipment at the filling station and the pressure regulators in the vehicle. The station itself is capable of fueling at 700 bar, the benchmark for heavy duty trucks, needed to provide fueling times comparable to diesel. fueling time is one of the primary advantages for hydrogen trucks over battery electric vehicles, which take hours to fully charge. The geno hydrogen refueling station is engineered for high capacity applications, making it the ideal choice for large fleets. capable of delivering up to 3,000 kg of hydrogen per day, the geno station supports fast, t40 350 and 700 bar fueling. it is designed to meet high demand refueling needs with consecutive back to back filling, making it. To 700 bar compressed gas hydrogen and a 33% improvement over liquid hydrogen, allowing cch2 trucks to achieve diesel equivalent range and payload. with more than 50 years of experience in the gas and cryogenics industry, cryostar has developed several liquid hydrogen pumps and hydrogen filling solutions for the hydrogen value.

Dual Pressure Hydrogen Refueling Station 350 700 Bar Hyfindr The geno hydrogen refueling station is engineered for high capacity applications, making it the ideal choice for large fleets. capable of delivering up to 3,000 kg of hydrogen per day, the geno station supports fast, t40 350 and 700 bar fueling. it is designed to meet high demand refueling needs with consecutive back to back filling, making it. To 700 bar compressed gas hydrogen and a 33% improvement over liquid hydrogen, allowing cch2 trucks to achieve diesel equivalent range and payload. with more than 50 years of experience in the gas and cryogenics industry, cryostar has developed several liquid hydrogen pumps and hydrogen filling solutions for the hydrogen value. Impact of refueling station configuration on refueling cost. accomplishment. fleet size: 30 buses fill amount: 35 kg fill rate: 3.6 kg min back to back. tube trailer hydrogen supply minimizes station cost for moderate sized fleets. tube trailer shifts cost upstream of station and has limited payload. Heavy duty fuel cell electric vehicles 4.1.tatus quo and future development s fuel cell electric vehicles (fcev) are already in use in various parts of the world. besides the use of hydrogen in pv in the longterm, the focus of fuel cell drivetrains is moving towards the hdv sector. since battery electric trucks and charging will, most 3 % %.

Comments are closed.